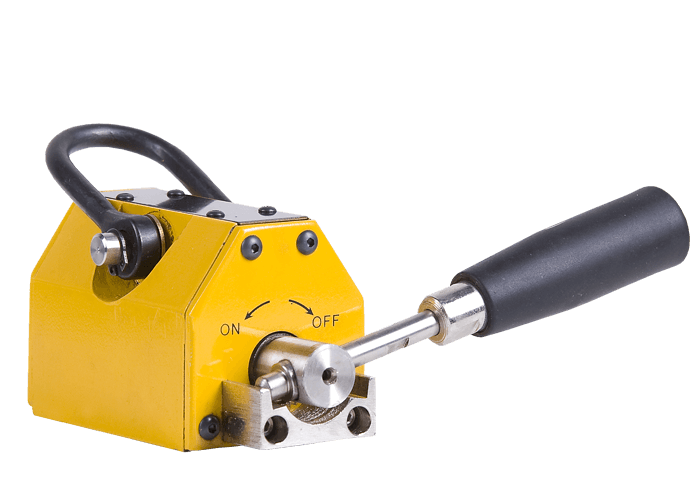

Magnetic Hold permanent lifting magnets accomplish what most electromagnets do without a need for electrical power. They utilize rare earth permanent magnets to produce an attraction that can be used for holding, loading, unloading and transporting heavy ferrous steel pieces. Our lifting magnets are designed with safety and simple operation in mind.

Benefits of Permanent Lifting Magnets

- Consistent strength with an on/off handle which features a safety device to prevent accidental movement of the on-off handle

- Does not require electricity

- Ease of use, usually requiring only one person to operate

- Compact and lightweight

- Causes less damage to the transported material, compared to a typical crane or hook

Lift magnets can be used across plants that handle steel and iron products. They can be used to move material from small rods or plates to large, heavy blocks. The lack of electrical power needed comes as a great advantage to those who use lifting magnets, avoiding the possibility of an electrical failure. The safety feature prevents the accidental dropping of the lifted material. The constant magnetic force allows for the dependability that the metal material can easily be transported.

Lifting magnets can be used in multiples to lift loads larger than the maximum weight requirements. When utilizing multiple magnets, the magnets must be spaced evenly using a spreader bar. Contact us to discuss your lifting needs and find out how we can help you make your process easier and more efficient.

SAFETY NOTES: Never stand under load being lifted. Always use extra caution. Only use magnetic lifts on material that does not flex or bend. The surface of the lift and the load need to be clean & free of chips, oil, slag, dirt, etc. Lift must be centered on the load. Not recommended for paint or finish coated surfaces. Operating Temperature shall be -40°C to +80°C and without strong vibration and impact.

Our LM100A, LM300A, and LM600A permanent lifting magnets have a lifting power of 100, 300, and 600 Kgs respectively for flat objects and 50, 150 and 300 Kgs respectively for cylindrical objects. Lifting magnets can be used in multiples to lift loads larger than the maximum weight requirements. When utilizing multiple magnets, the magnets must be spaced evenly using a spreader bar. Contact us to discuss your lifting needs and find out how we can help you make your process easier and more efficient.

LM100A-LM600A Permanent Lifting Magnet Specifications

| Part Number | Lifting * Power For a Flat Object (Kgs) | Max Plate Length (mm) | Lifting * Power For a Cylindrical Object (Kgs) | Max Round Bar Length (mm) | A (mm) | B (mm) | C (mm) | D (mm) | E (mm) | F (mm) | G (mm) | Max Operating Temperature (Deg C) |

Weight (KG) |

Pricing (ea) |

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| LM100A | 100 | 1000 | 50 | 1500 | 86 | 150 | 66 | 67 | 63 | 35 | 43 | 80 | 4.5 | $200 |

| LM300A | 300 | 1500 | 150 | 1500 | 180 | 168 | 80 | 80 | 63 | 35 | 43 | 80 | 10 | $275 |

SAFETY NOTES: Never stand under load being lifted. Always use extra caution. Only use magnetic lifts on material that does not flex or bend. The surface of the lift and the load need to be clean & free of chips, oil, slag, dirt, etc. Lift must be centered on the load. Not recommended for paint or finish coated surfaces. Operating Temperature shall be -40°C to +80°C and without strong vibration and impact.