INDUSTRIAL CERAMIC MAGNETS

Magnetic Hold is a leading ceramic magnet manufacturer. What sets us apart from our competitors are our quality goods, workmanship, low prices, and our commitment to 100% customer satisfaction. What is important to us the most is our customers and their needs, not the size of their orders. At Magnetic Hold, customer service is our commitment

WHAT IS A CERAMIC MAGNET?

Ceramic Magnets are also known as Hard Ferrite Magnets, are composed of barium or strontium, were developed in the early 1960's as an alternative to the more expensive metallic magnets. This class of magnet is very hard, brittle and possesses lower energy characteristics compared to other magnetic materials. However, ceramic ferrite magnets are very popular and widely used because of its excellent resistance to demagnetization, corrosion, and the advantageous pricing.

Sintering, or injection molding manufactures ferrite magnets. Ceramic magnets retain about 45% of their room-temperature magnetic specifications at 350 °F. Degradation with increasing temperature is nearly linear, and changes in magnetization are essentially reversible up to approximately 840 °F, at which temperature ceramic magnets become completely demagnetized. Ceramic magnets exposed to temperatures up to 1800 °F can be remagnetized for continued use. However, changes are irreversible above 1800 °F.

Ceramic 5 magnets are the most commonly used and must be magnetized in the direction of their orientation.

Ceramic 8 magnets are used for their excellent peak energy product and greater resistance to demagnetization than Ceramic 5 magnets. They also must be magnetized in the direction of their orientation. Ceramic 8 is an excellent choice wherever magnet length is at minimum or where the magnetic circuit is subject to severe demagnetizing field. See table below for grades and properties of Ceramic magnets.

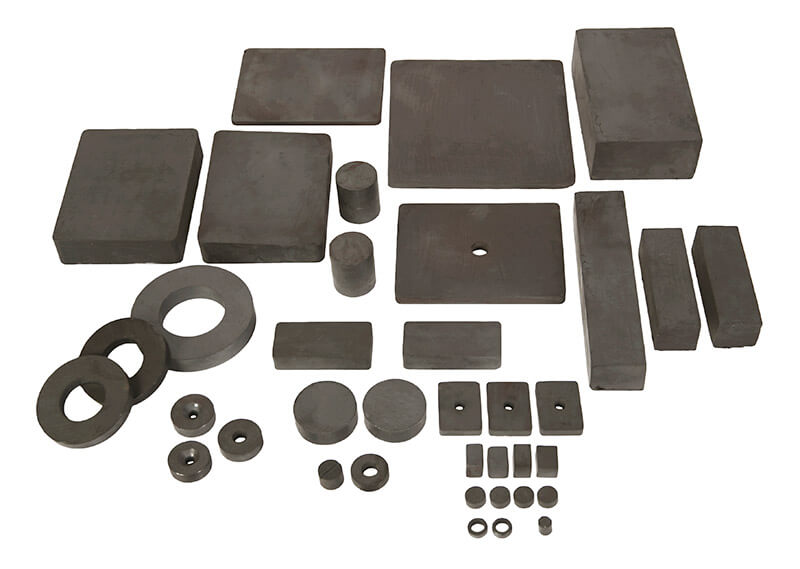

CERAMIC FERRITE MAGNET SHAPES

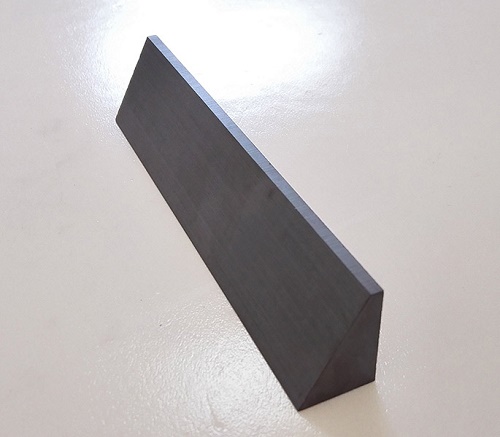

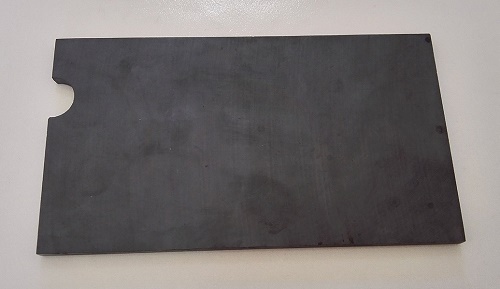

Magnetic Hold can manufacture ceramic magnets in a wide variety of shapes, including ceramic ring & block magnets. Below is a list of the most popular and common shapes that are requested for ceramic magnets. If the shape you're looking for isn't listed below, then fill out our custom form!

- Arc

- Bar

- Rod

- Disc

- Horseshoe

- Channel

- Block

- Ring

- Sphere

- Cylinders

- Plugs

Ceramic Magnet Applications

- Speaker magnets

- DC brushless motors

- Magnetic Resonance Imaging (MRI)

- Magnetos used on lawnmowers and outboard motors

- DC permanent magnet motors (used in cars)

- Separators (separate ferrous material from non-ferrous)

- Used in magnetic assemblies designed for lifting, holding, and retrieving

- Reed switches

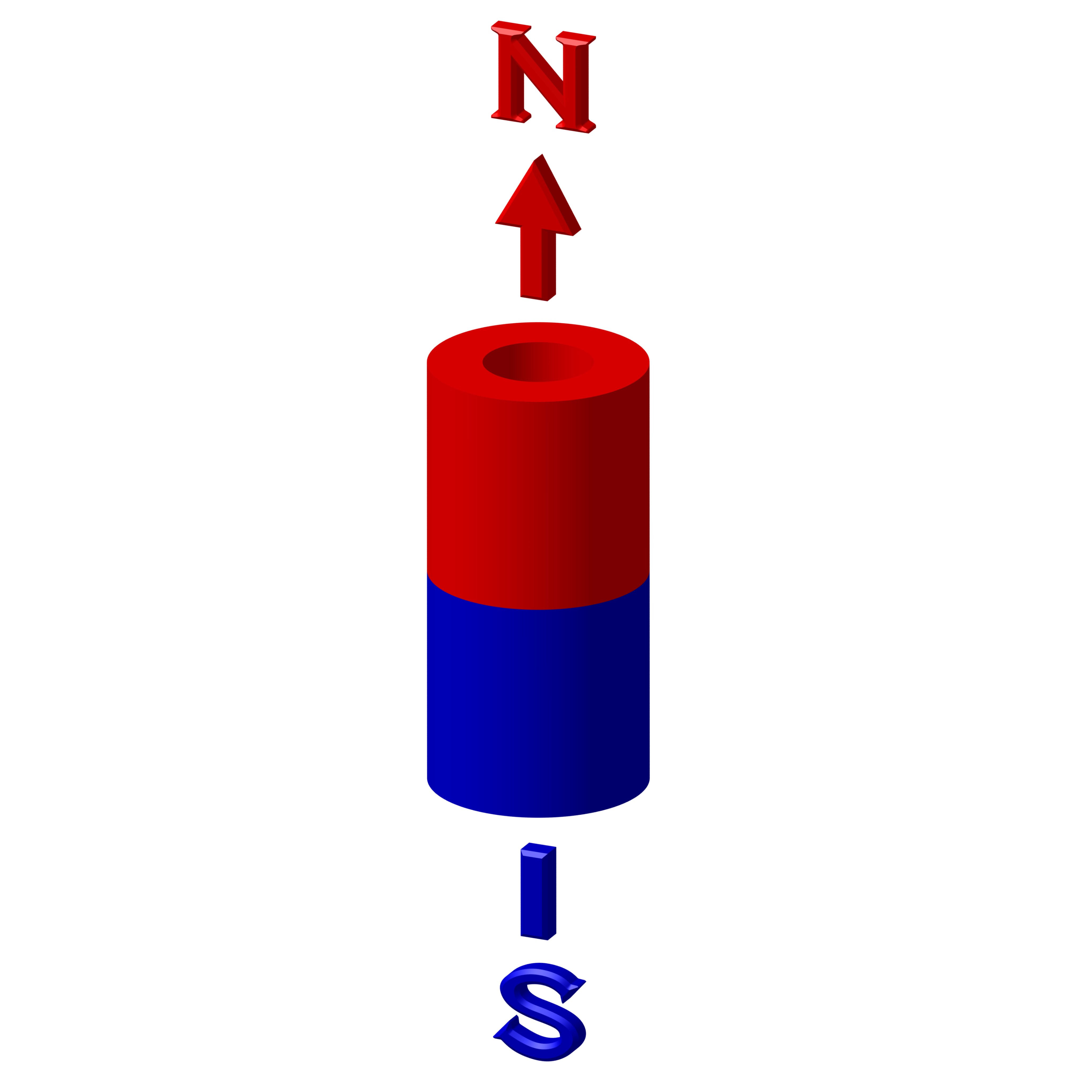

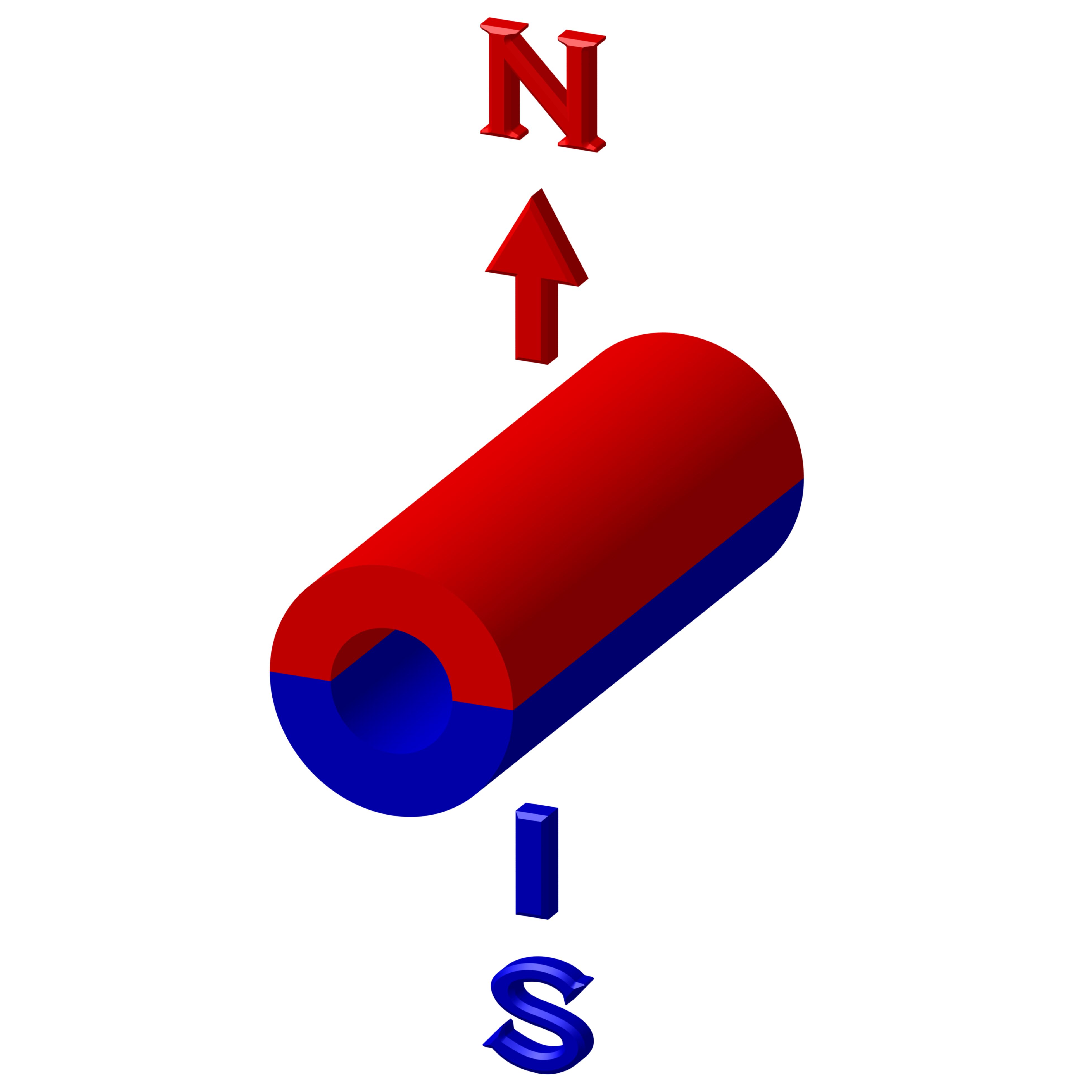

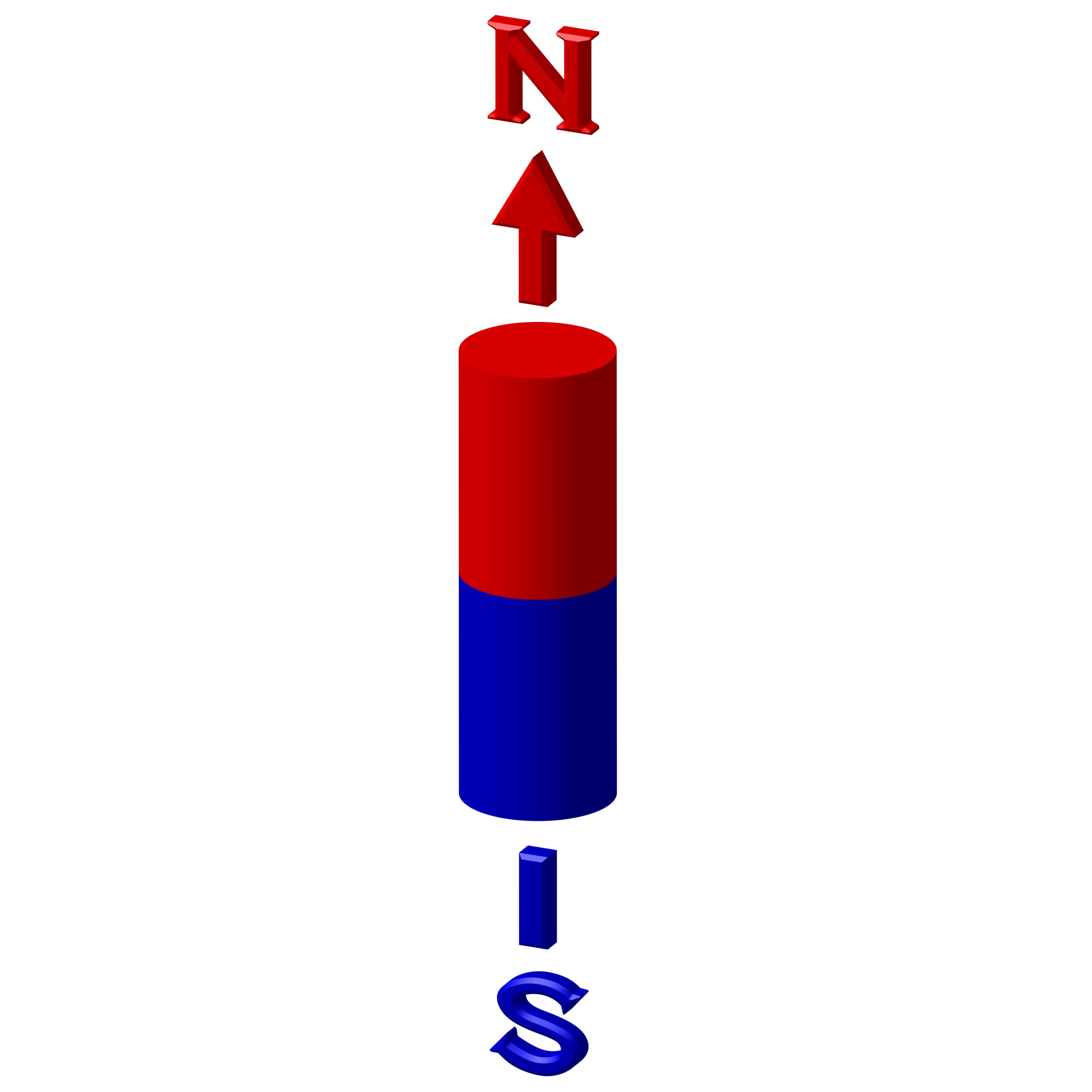

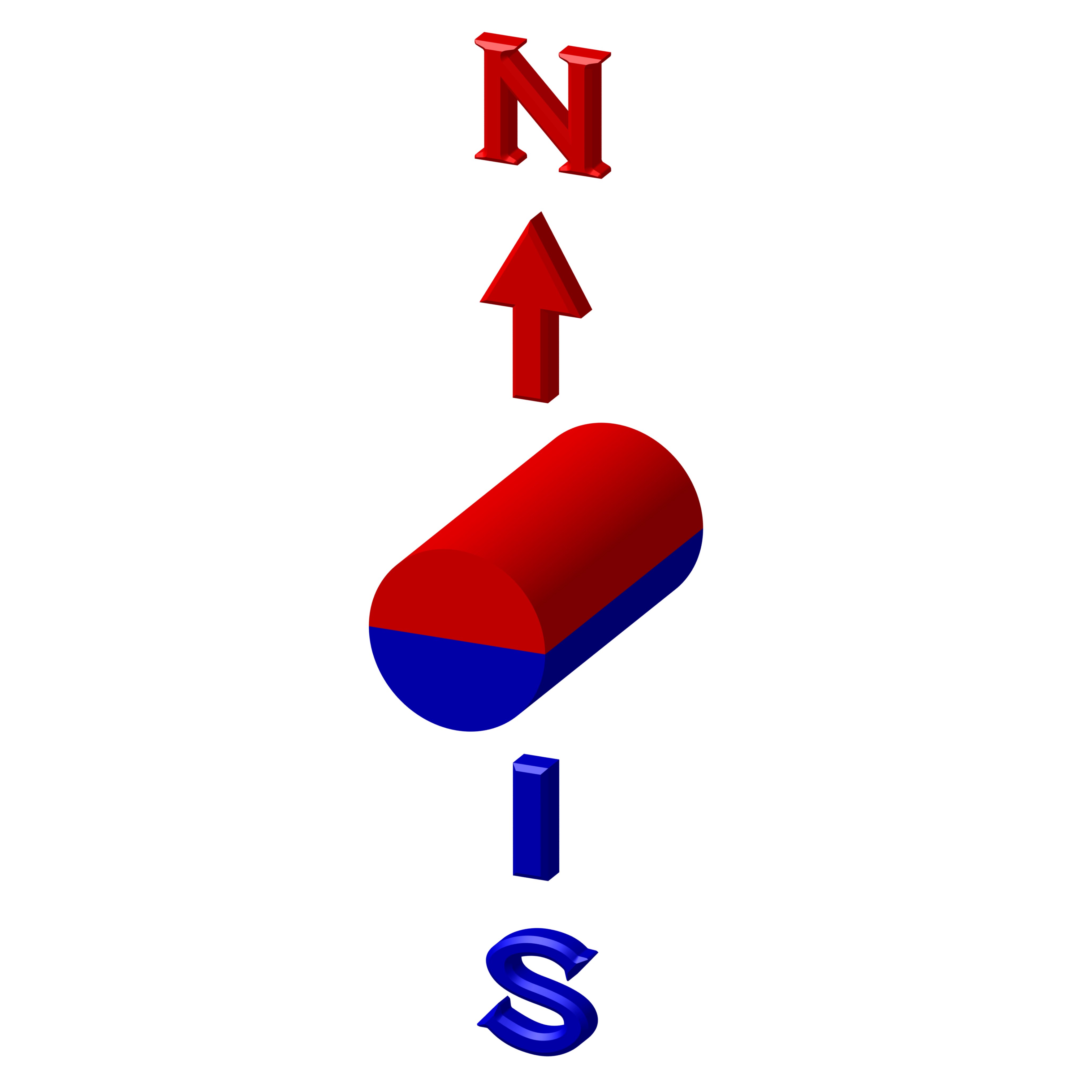

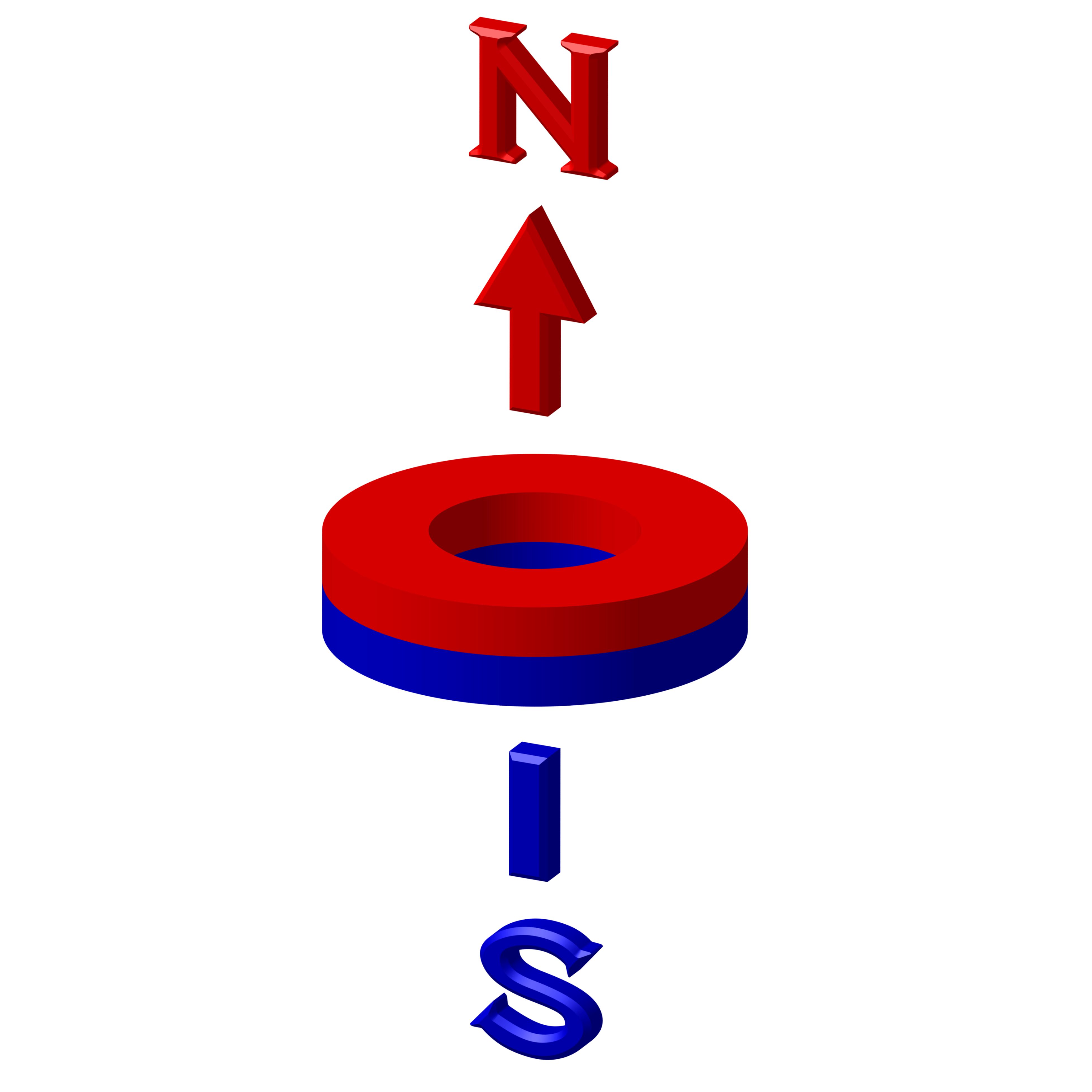

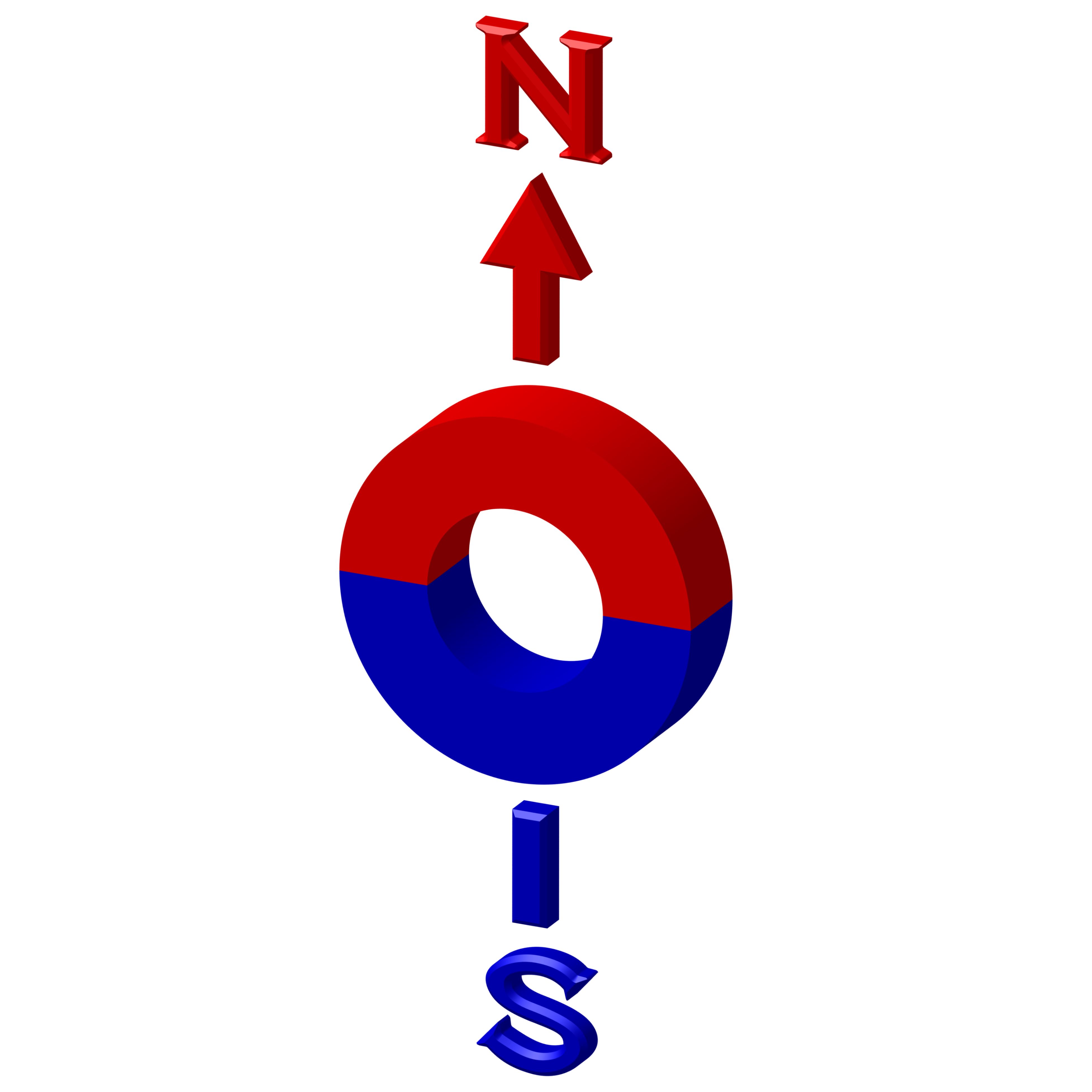

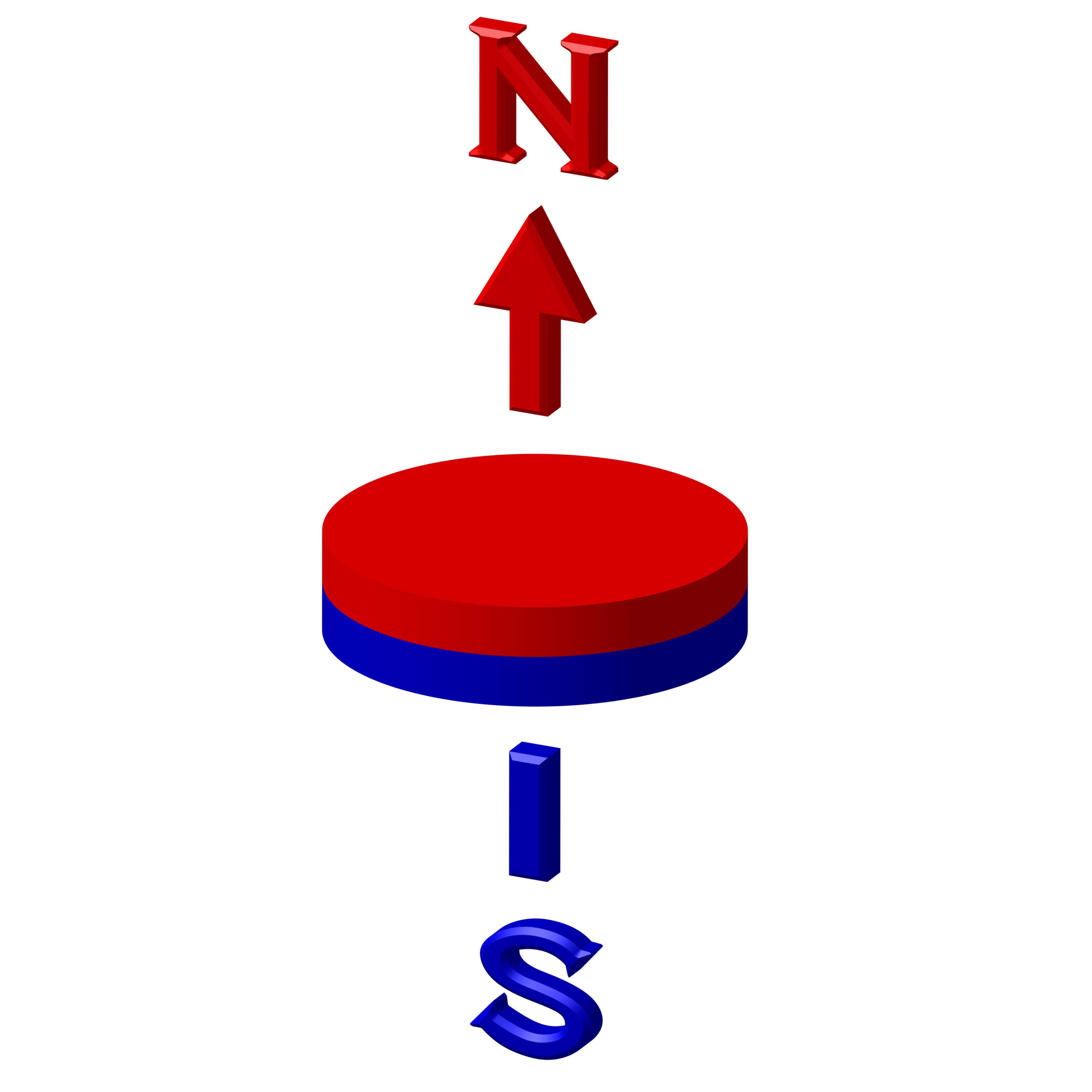

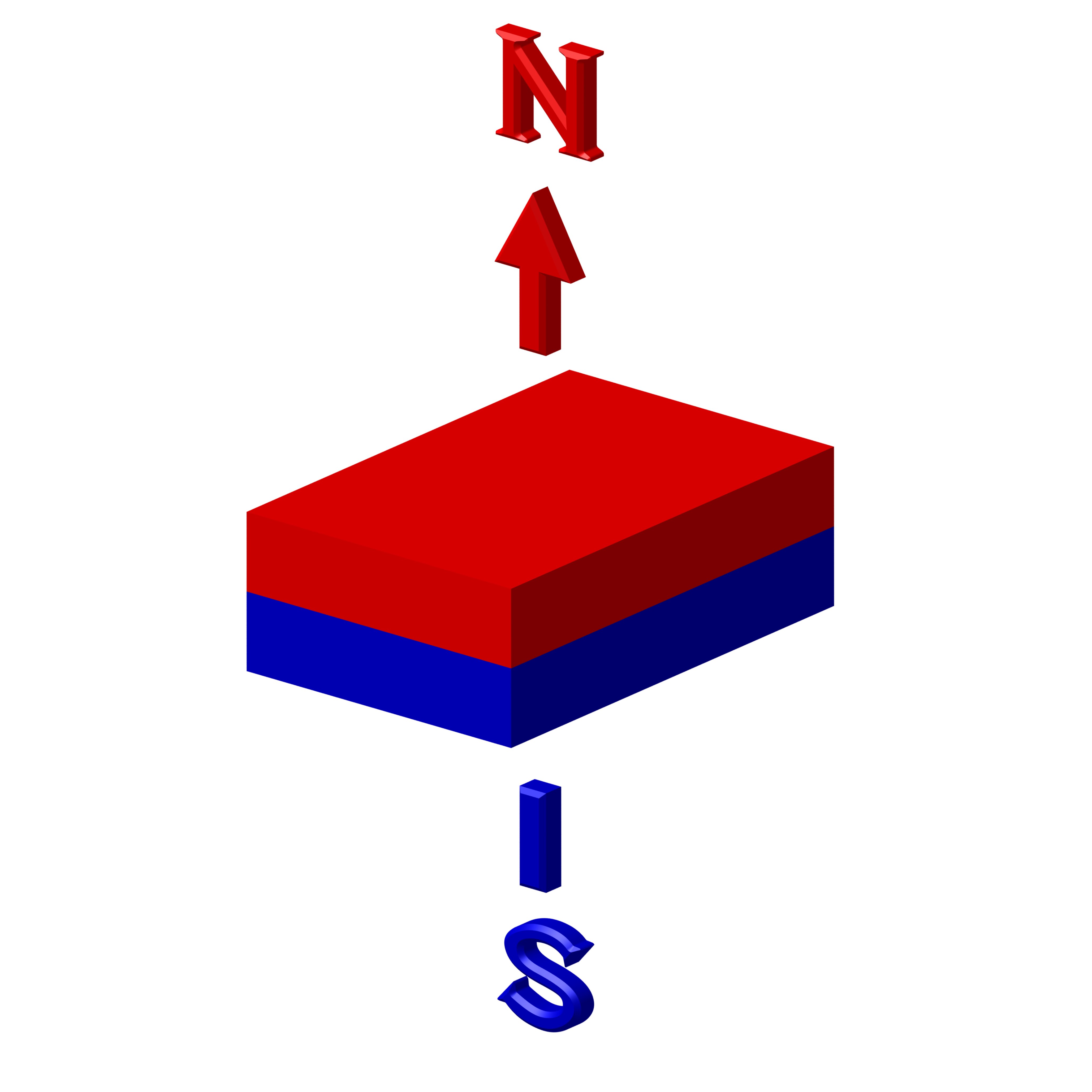

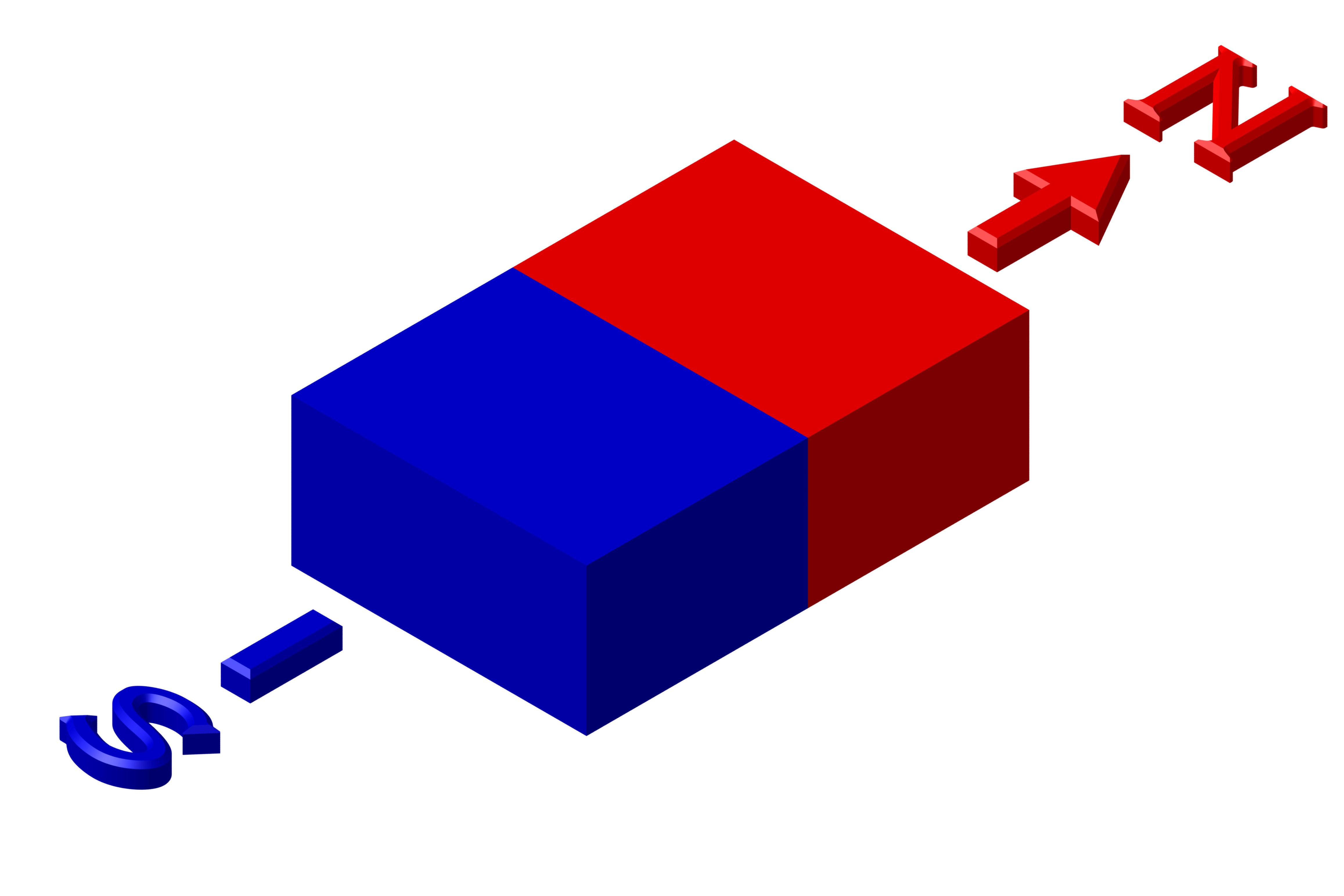

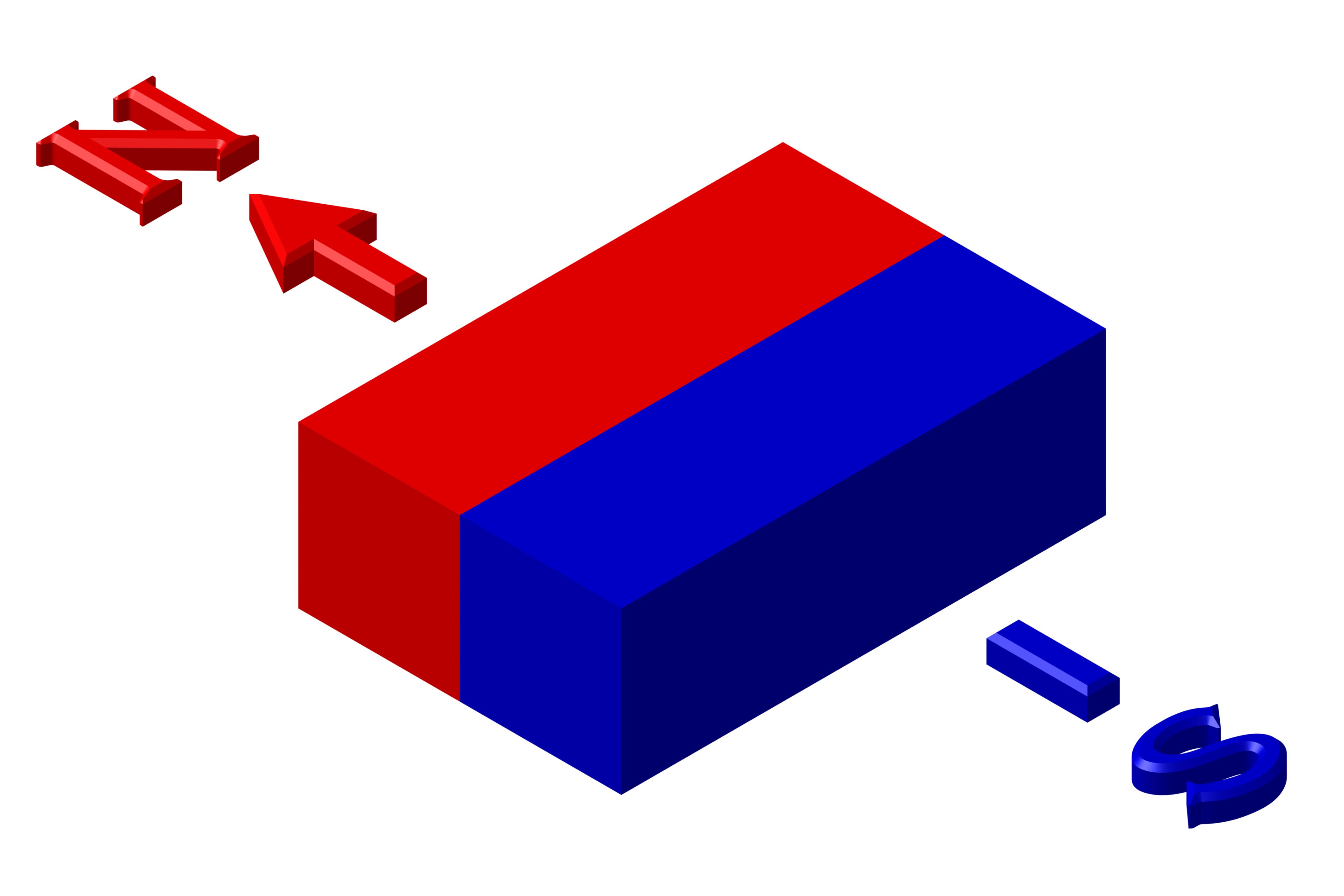

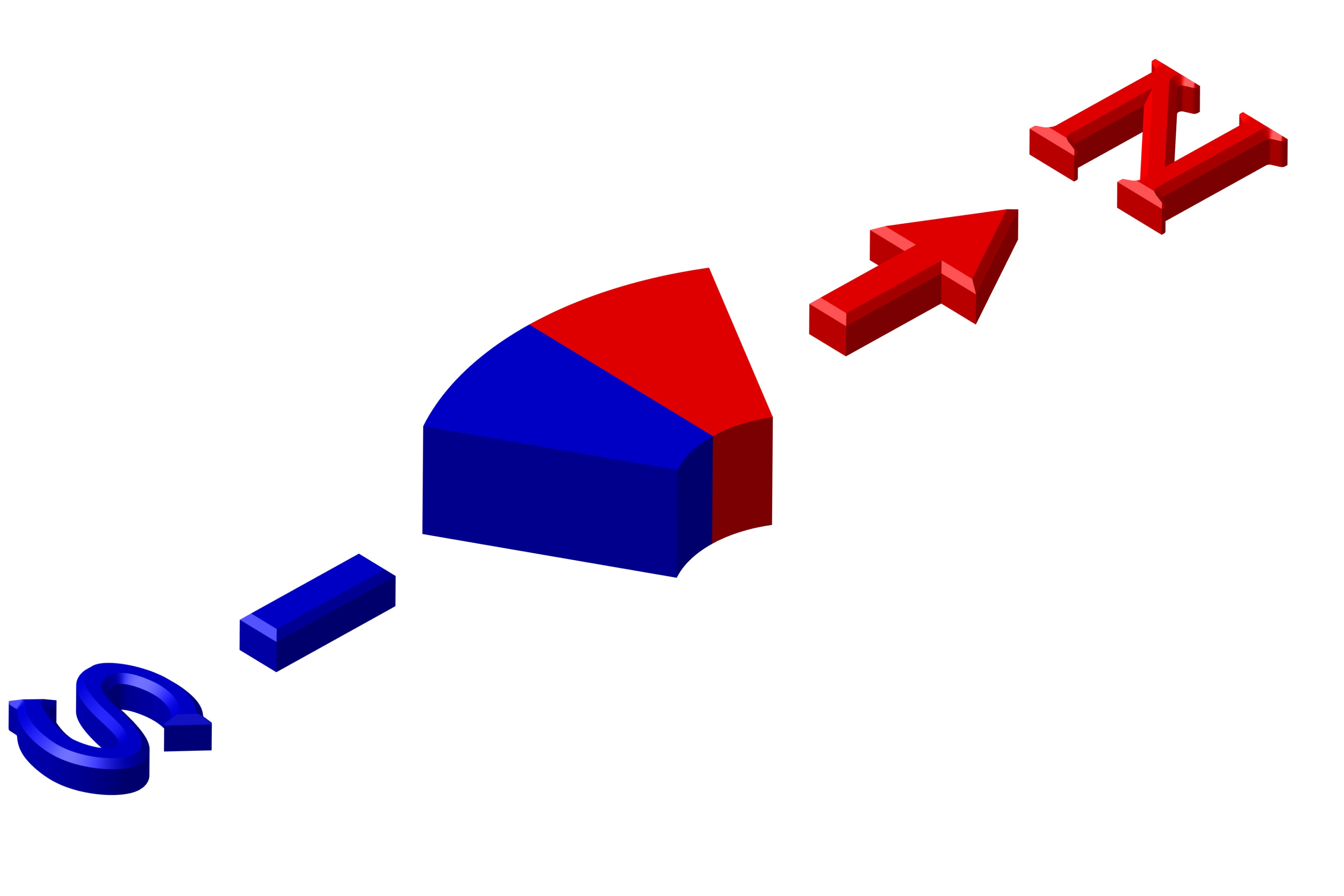

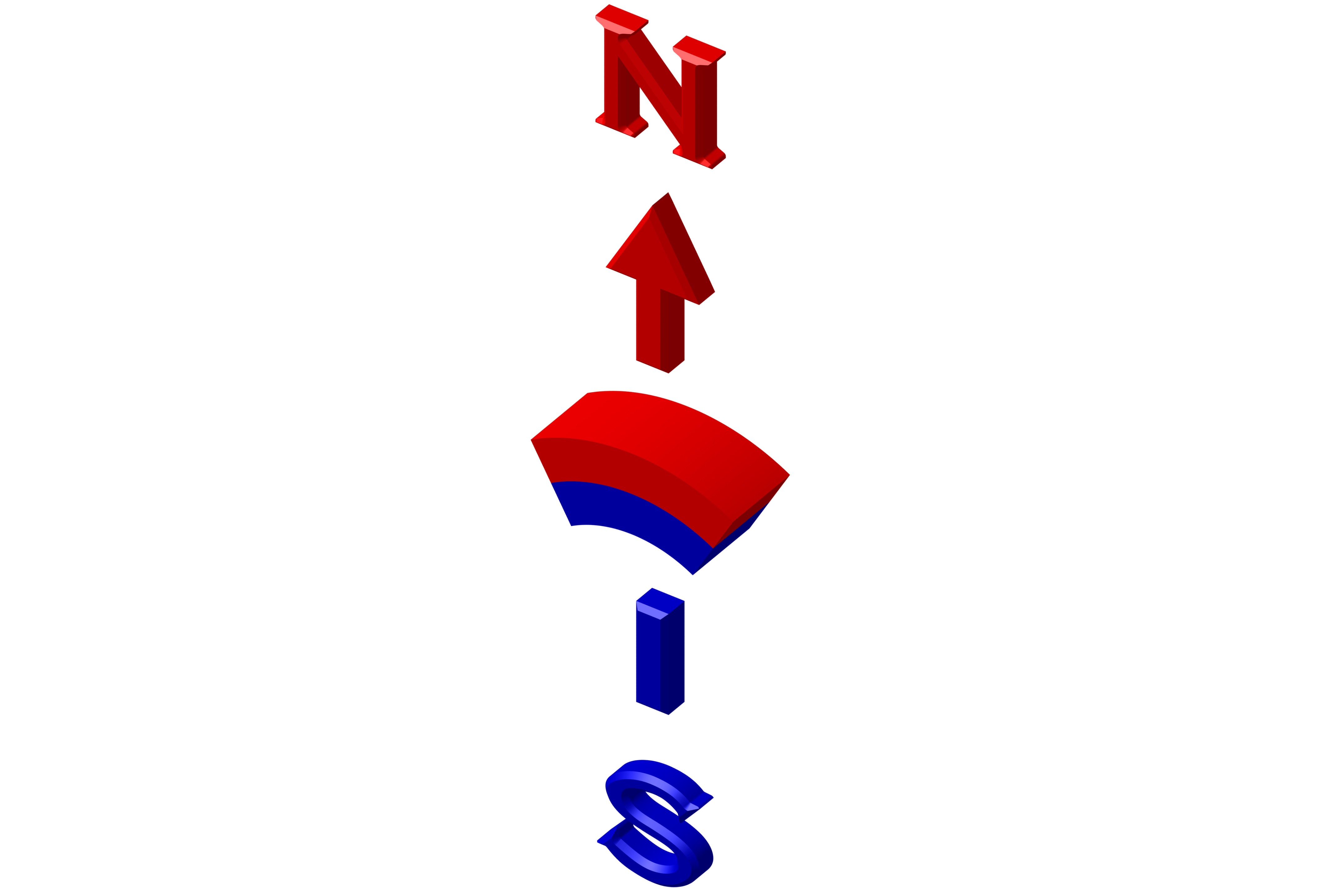

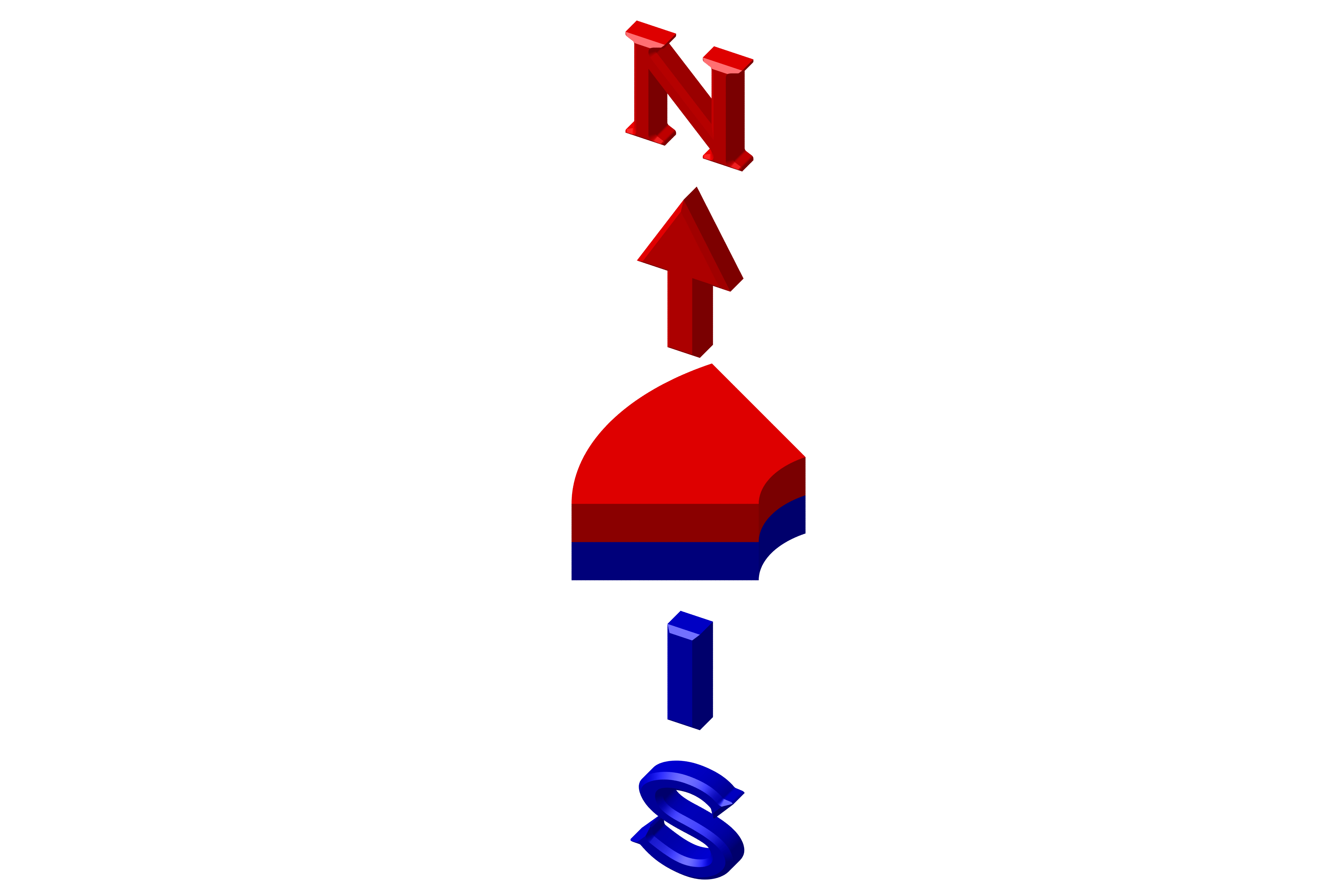

Magnetism Direction Options

We can offer several different magnetization directions, see below schematics. Their availability is limited to size. Magnetization fixture cost may apply for large and custom magnets with magnetization other than what is shown below

Ceramic Magnet Grades & Properties

| Grade | Residual Induction Br (max) [Gs] | Max Energy Product BH (max) MGOe | Coercive Force Hcb Koe | Curie Temp. [˚C] | Temp. Coe of Br [%/˚C) | Max. Practical Operating Temp. [˚C] |

|---|---|---|---|---|---|---|

| Ceramic 1 (Isotropic) |

2000 | 1.05 | 1.8 | 450 | -0.2 | 250 |

| Ceramic 5 (Anisotropic) |

3900 | 3.4 | 2.4 | 450 | -0.2 | 250 |

| Ceramic 8 (Anisotropic) |

3900 | 3.5 | 2.9 | 450 | -0.2 | 250 |

Br: Residual Induction

Gs: Gauss

Hc: Coercive Force

Oe: Oersted

˚C: Degree Celcius

MGOe: Mega Gauss Oersted

Standard Tolerances (inches);

Rod - Diameter (±0.002), Length (±0.005)

Rectangle – Length & Width (±0.01), Thickness (±0.005)

Ring – Outside Diameter (±0.002), Inside Diameter (±0.02), Thickness (±0.005)