Alnico Magnets

Magnetic Hold is a leading cast & sintered alnico magnet provider. What sets us apart from our competitors are our quality goods, workmanship, low prices, and our commitment to 100% customer satisfaction. What is important to us the most is our customers and their needs, not the size of their orders. At Magnetic Hold, customer service is our commitment.

What is an Alnico Magnet?

Alnico magnets, composed of primarily aluminum (Al), nickel (Ni), and cobalt (Co), were developed in the 1940s. This class of magnet remains a preferred material because of its excellent temperature stability, high magnetic flux density, and resistance to corrosion.

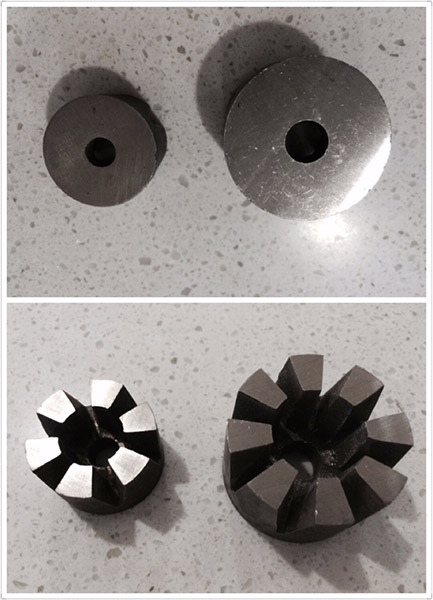

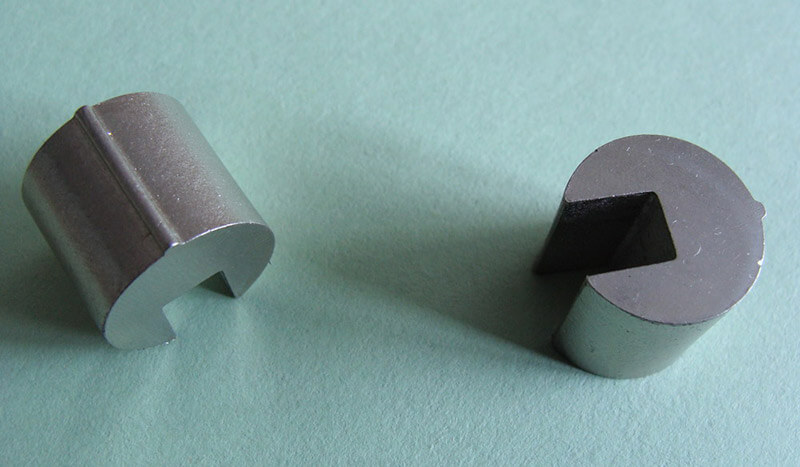

Alnico magnets are manufactured through a casting or sintering process. The casting process allows the magnet to be manufactured into intricate and complex shapes. Sintered Alnico is made from a powdered mixture of ingredients that are pressed into a die under tons of pressure. The Sintering process allows for the magnets to be manufactured to tighter tolerances and higher mechanical strength.

Alnico Magnet Applications

- Guitar pickups

- Separators

- Sensors

- Radar

- Holding magnets

- Coin acceptors

- Motors

- Relays

- Controls

- Generators

- Receivers

- Telephones

- Microphones

- Bell ringers

- Loudspeakers

- Security systems

- And much more

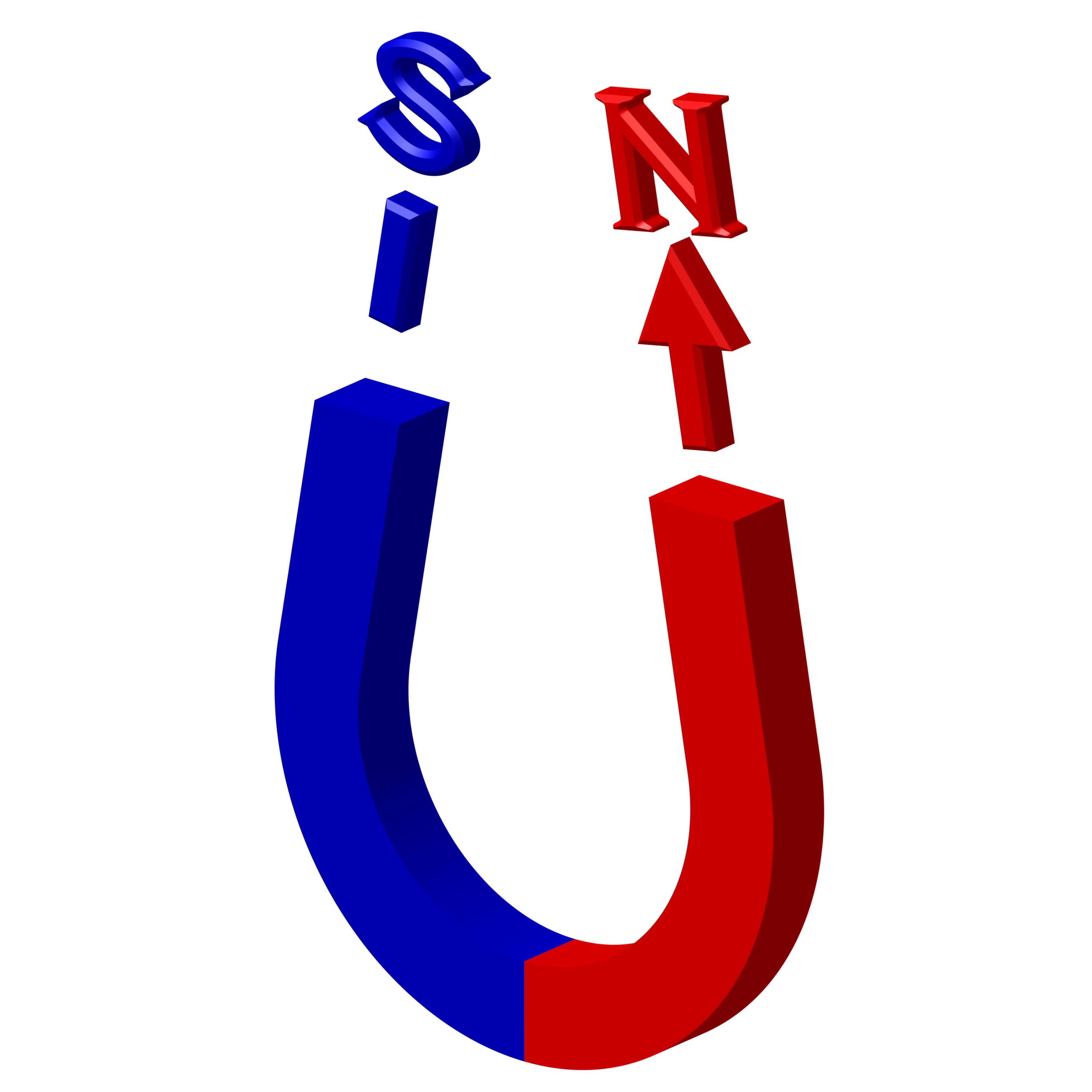

Custom Alnico Magnet Shapes

Magnetic Hold is an alnico magnet manufacturer and supplier with capabilities to customize any magnet shape. We work with you to personalize your magnets for your application. Common magnet shapes include:

- Rods

- Bars

- Assemblies

- Horseshoe

- C-shaped

- Cylinders

- Rings

- Channels

- Arc

- Disc

- Block

- Sphere

- Plugs

Cast Alnico Magnets

The most common Alnico cast magnets are in grades 1, 2, 3, 5, 6, 8, and 9. They are best suited for applications exposed to operating temperatures above 400 ° Fahrenheit. They maintain approximately 85% of their room-temperature strength up to 1000 ° F. They become completely demagnetized at approximately 1600 °F. For best results with Alnico 5 magnets, the length should be no less than 5 times the cross-section diameter or the diameter of a circle equal in area to the cross-section.

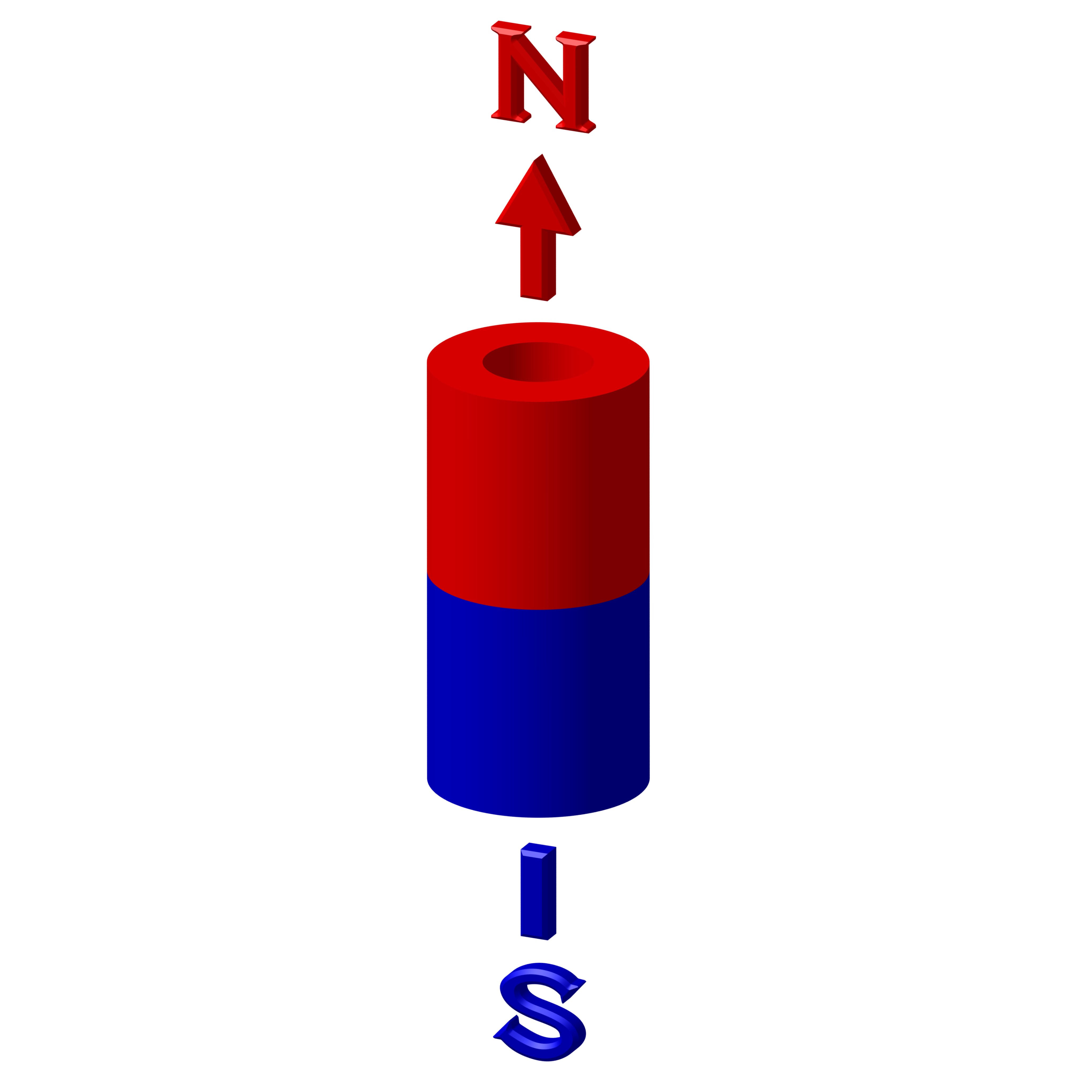

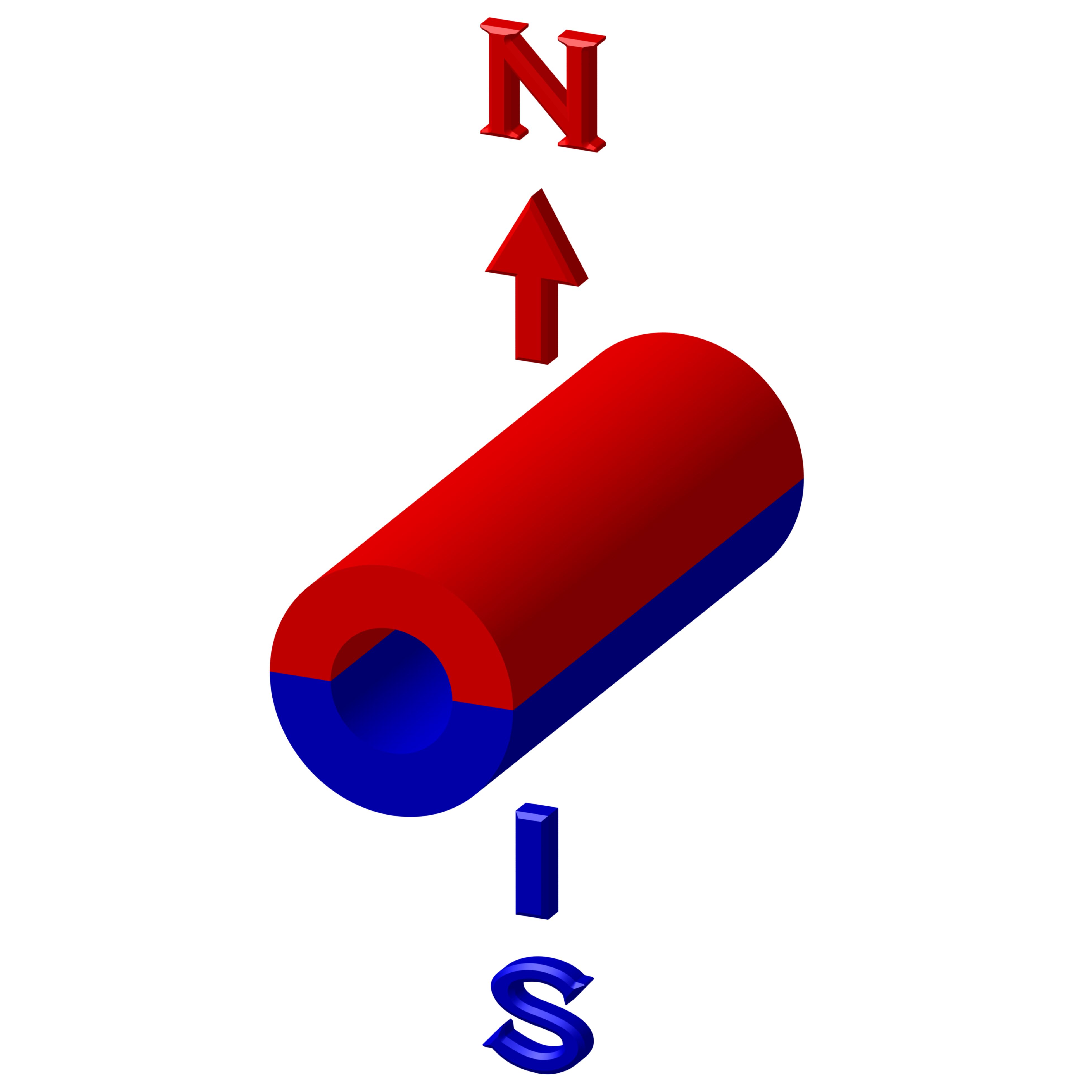

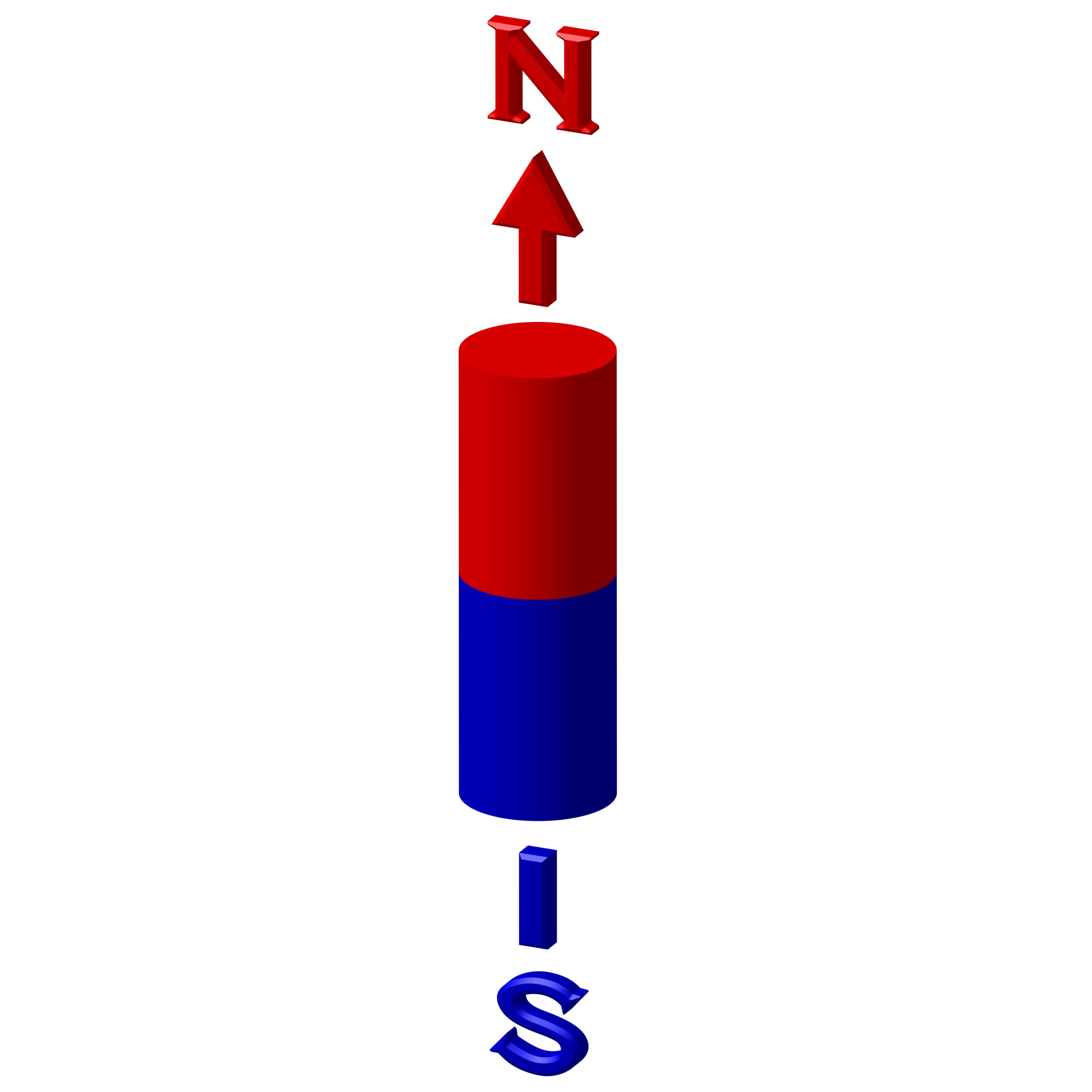

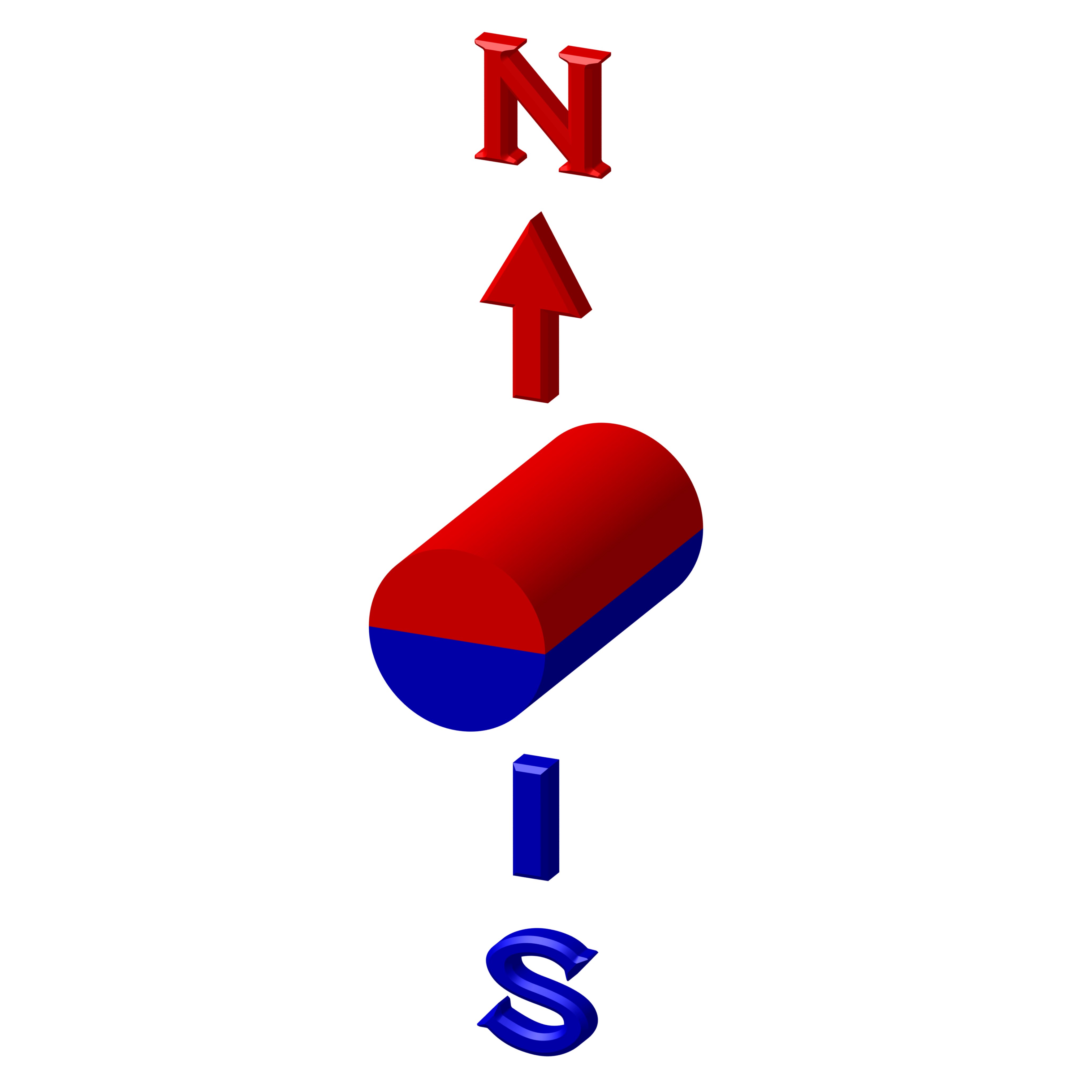

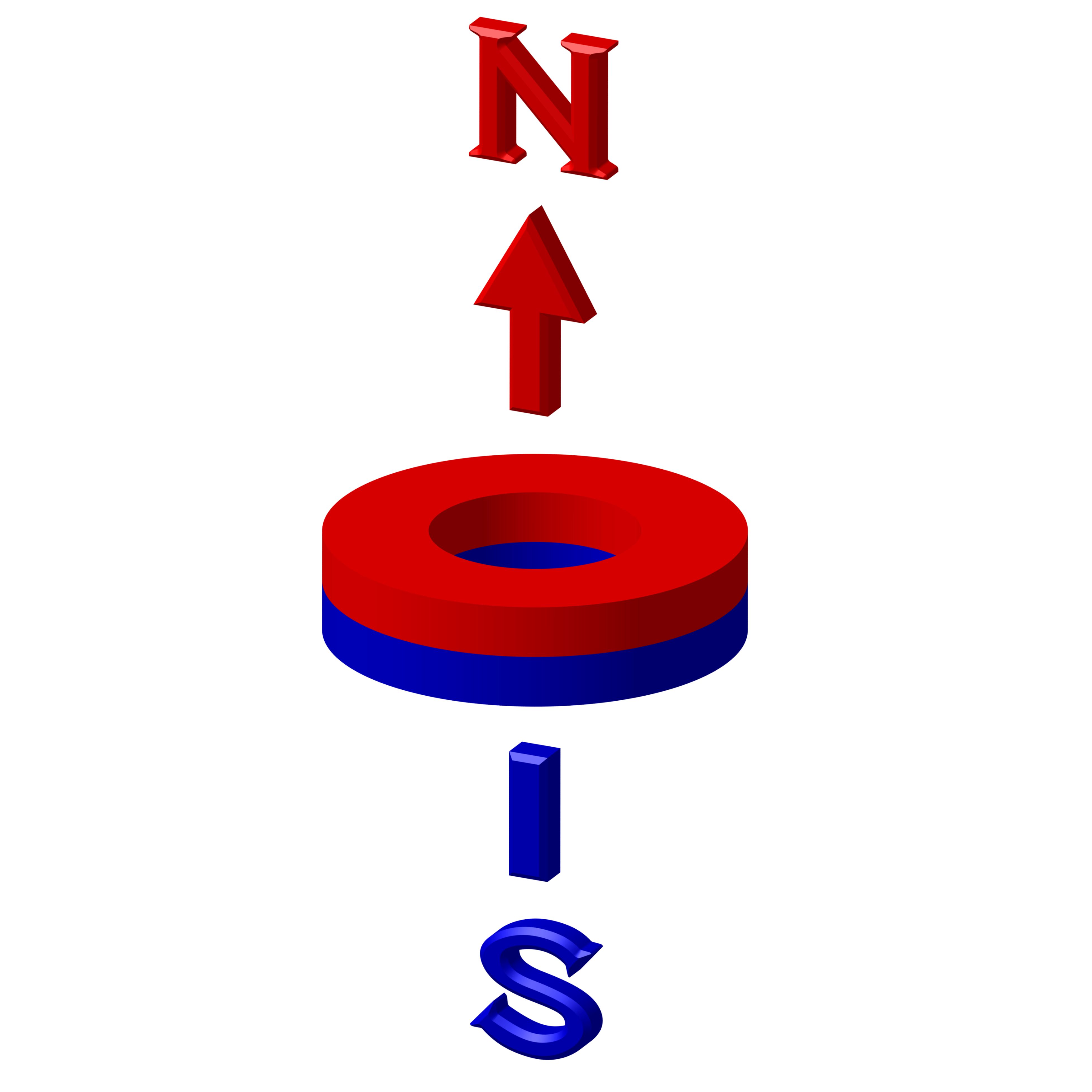

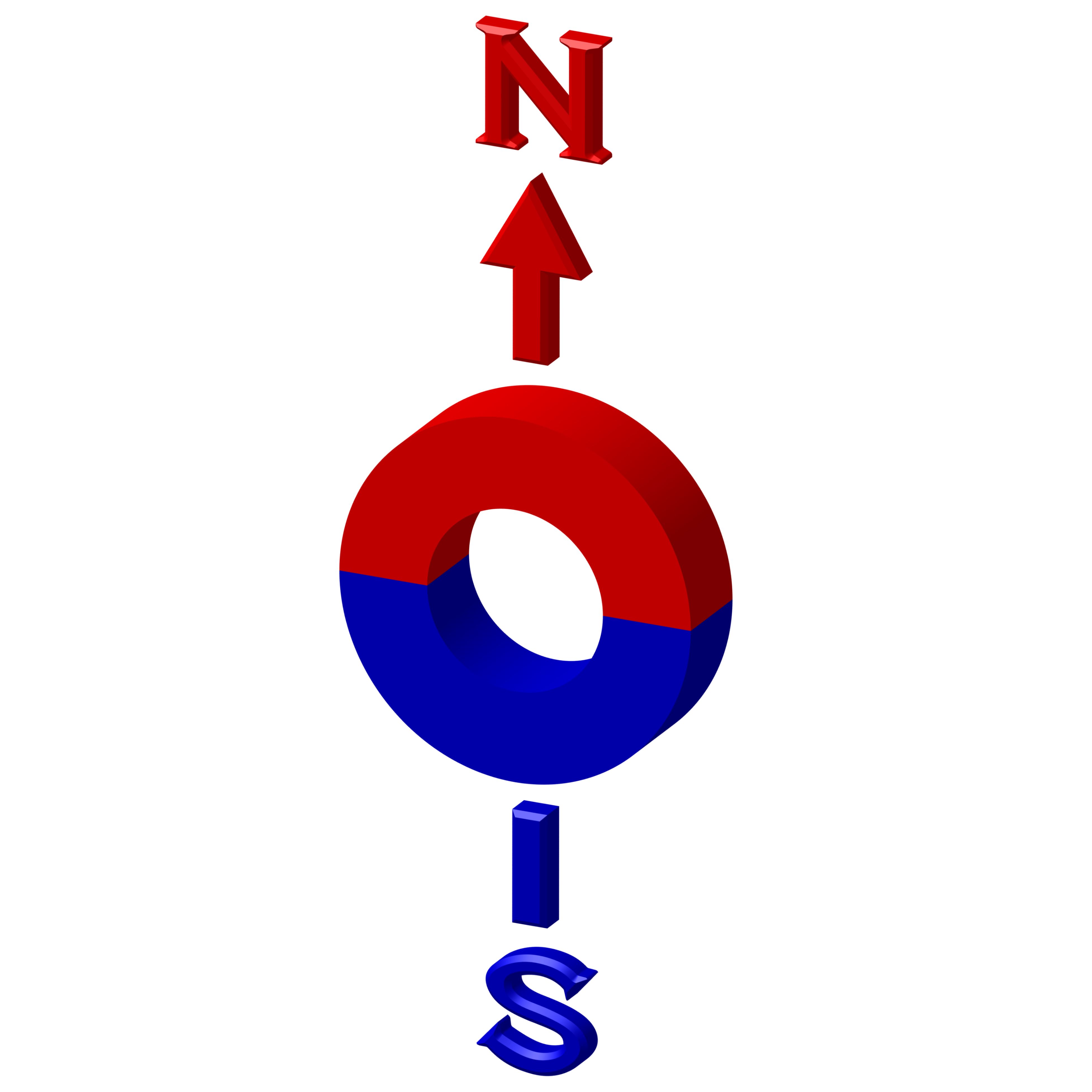

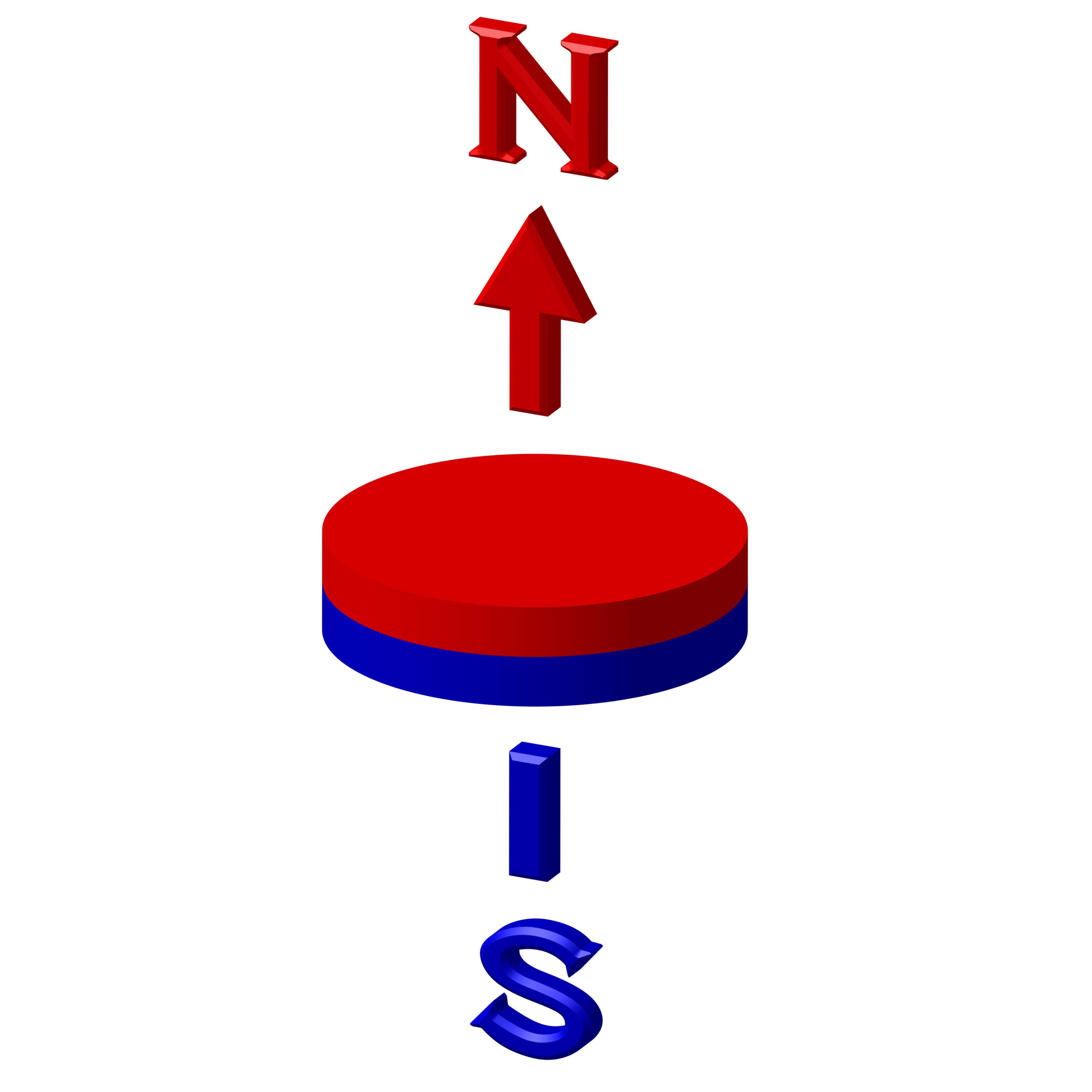

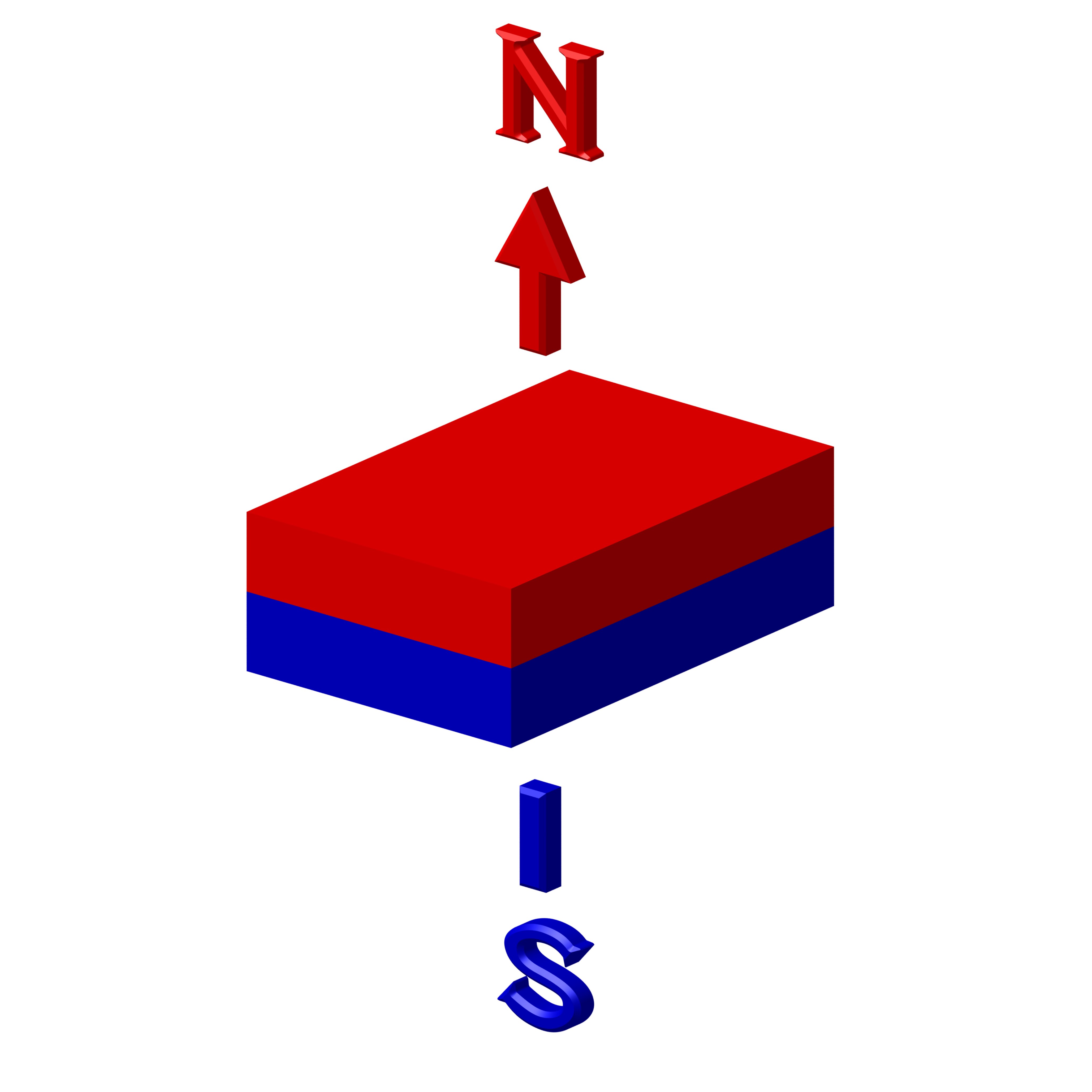

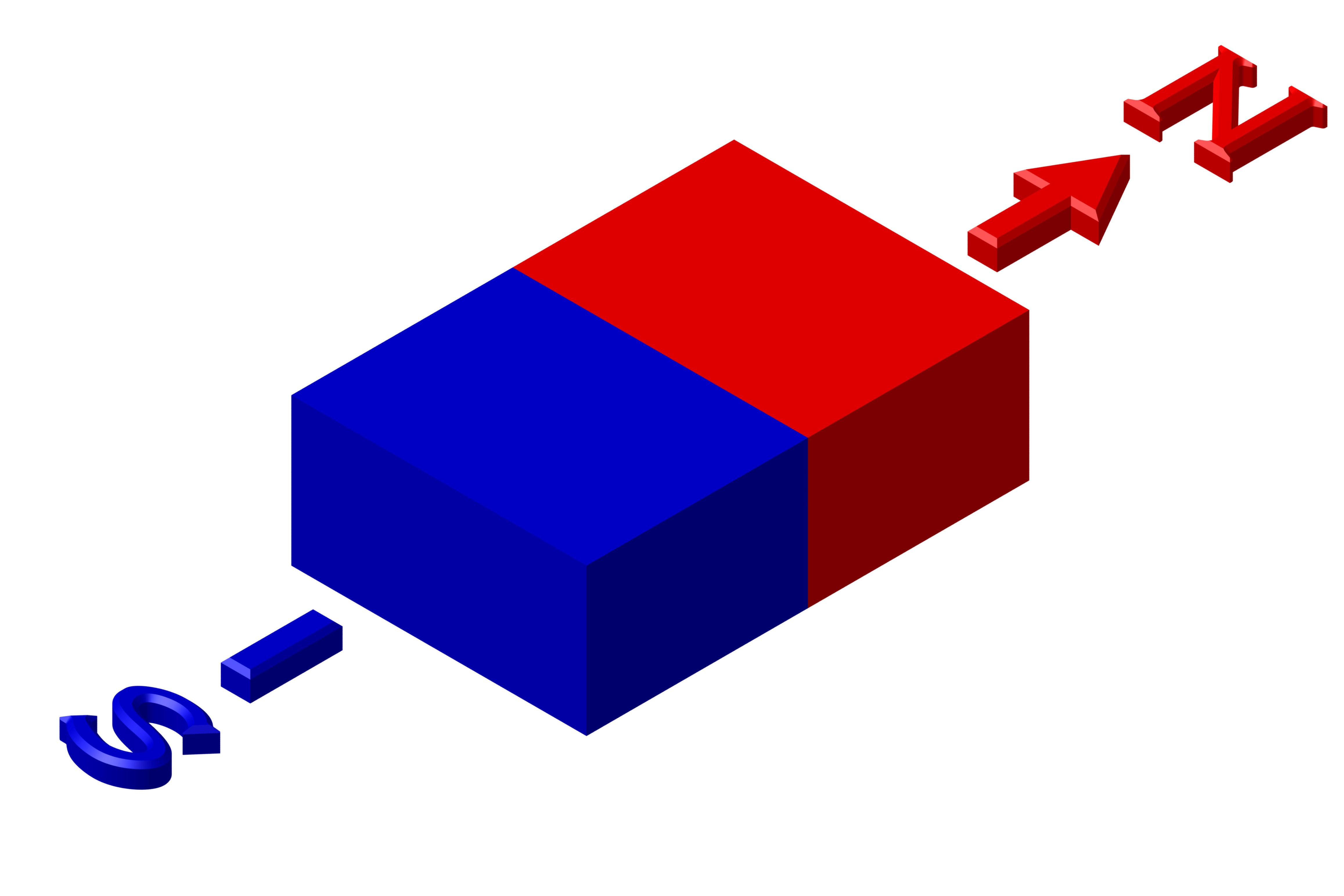

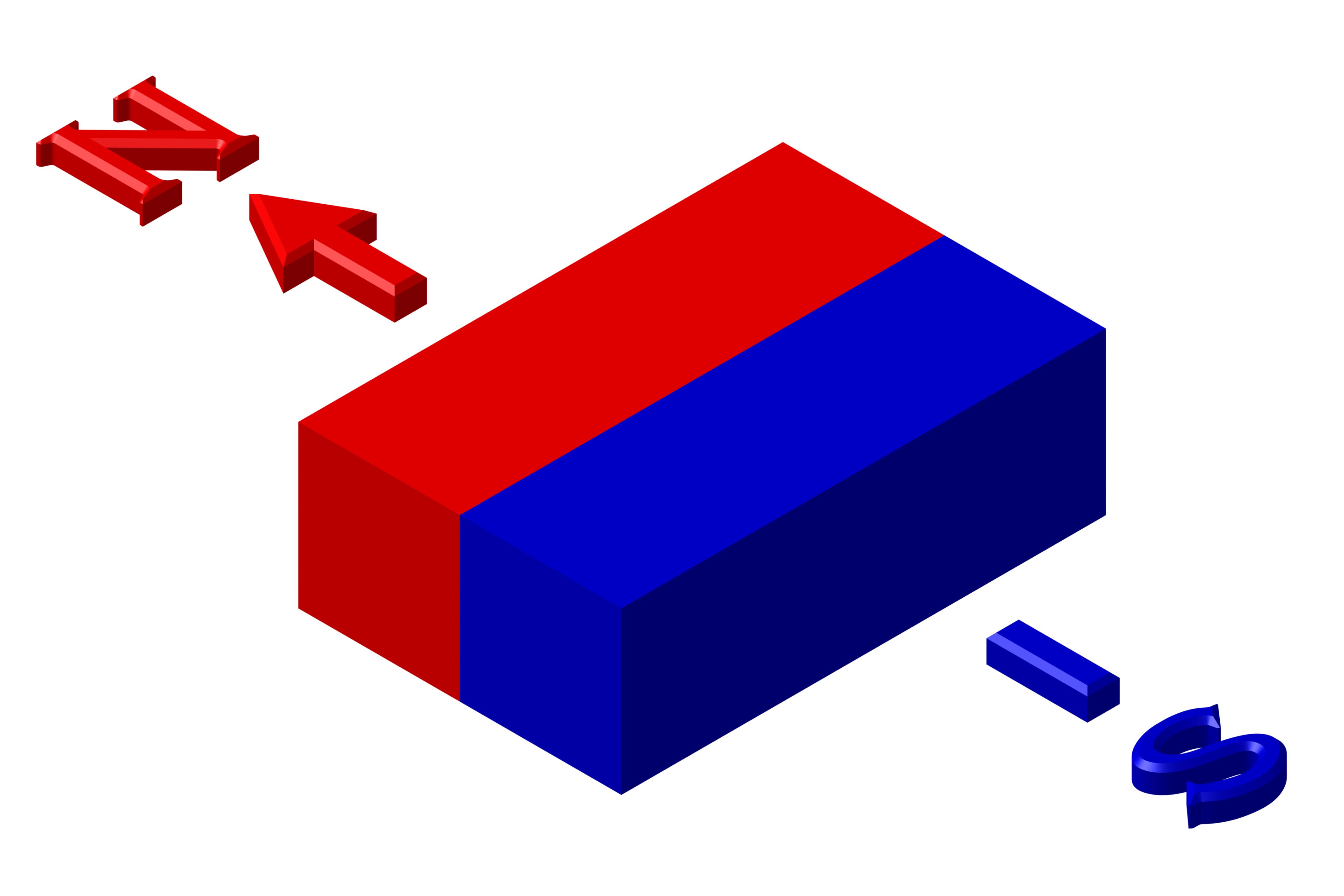

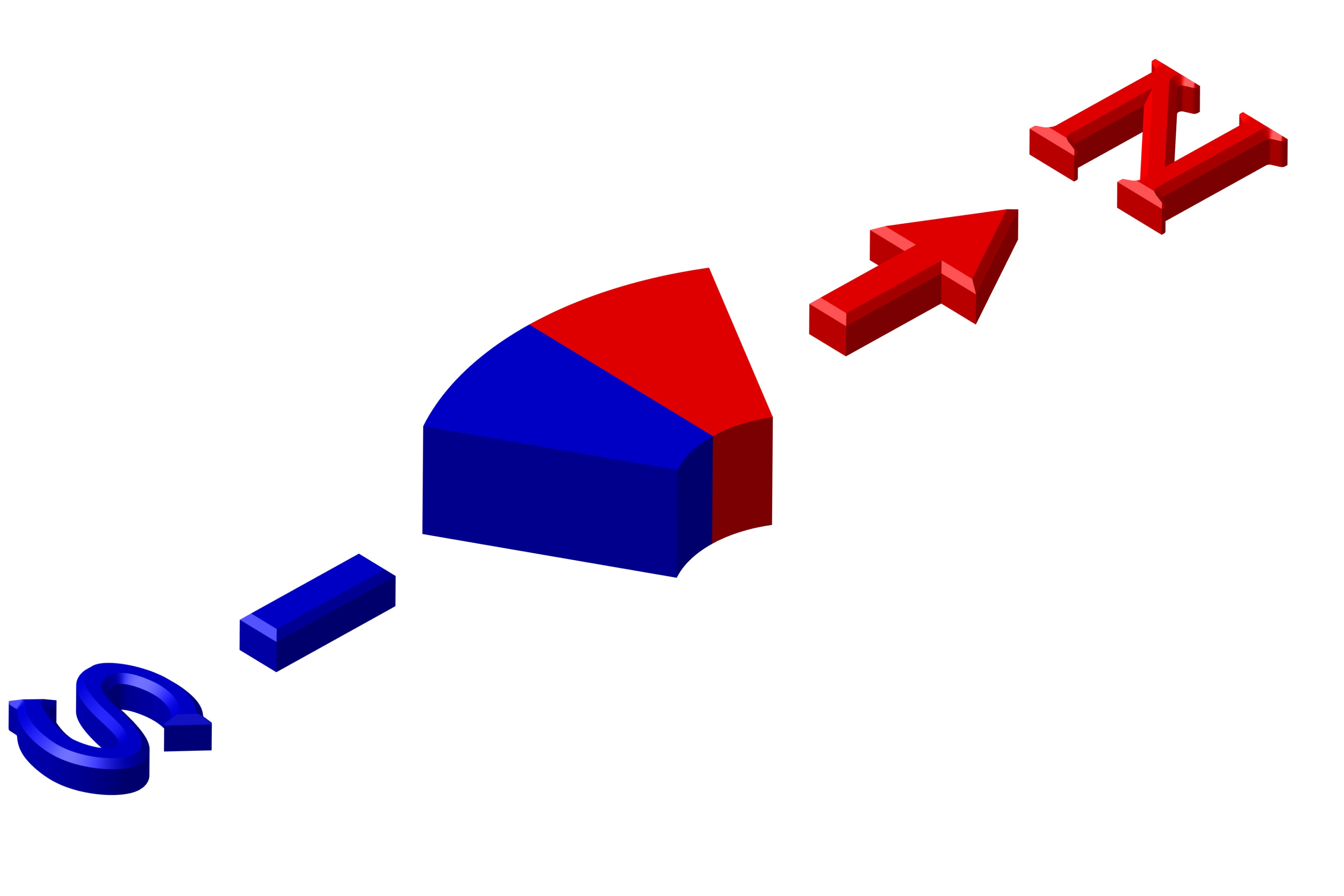

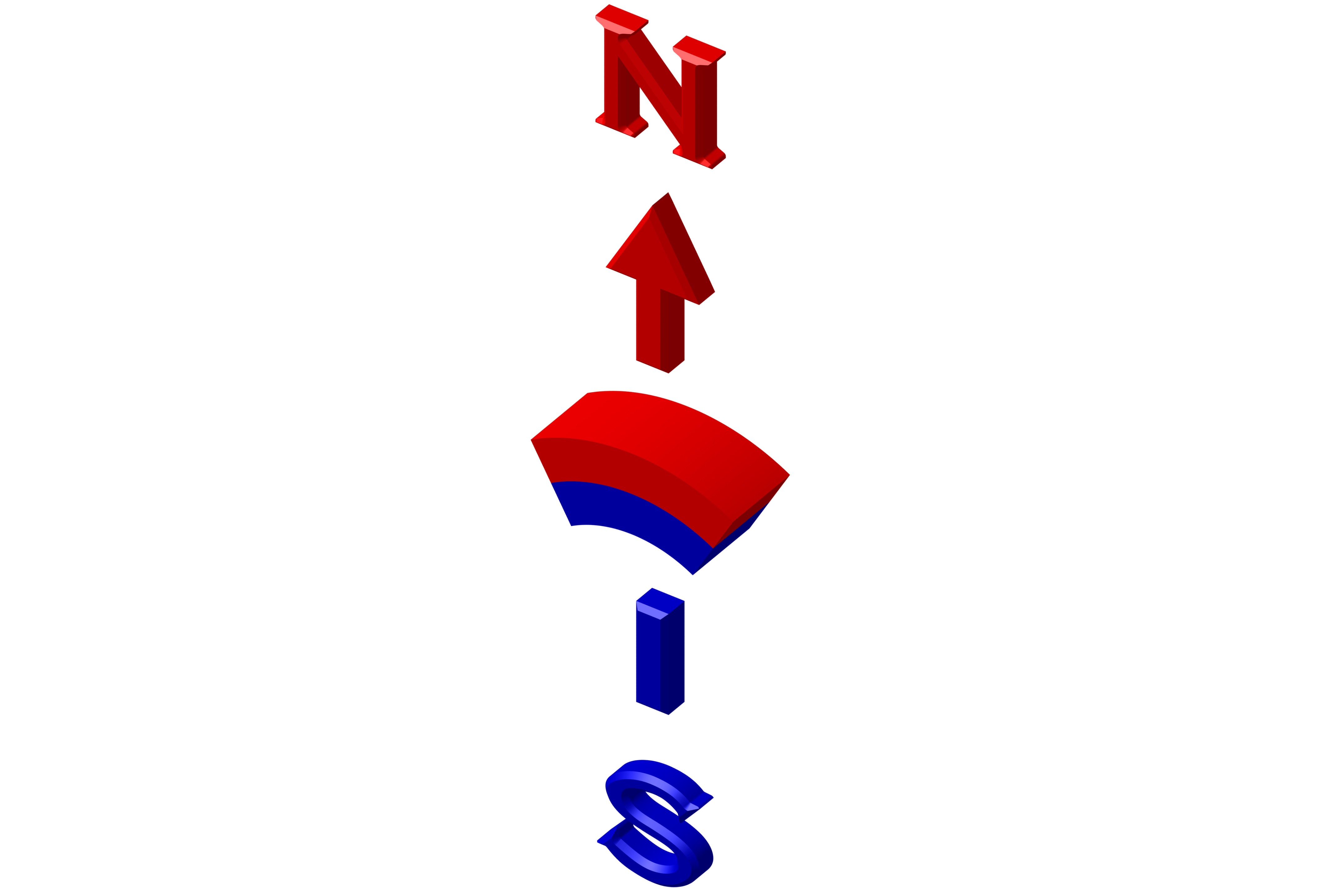

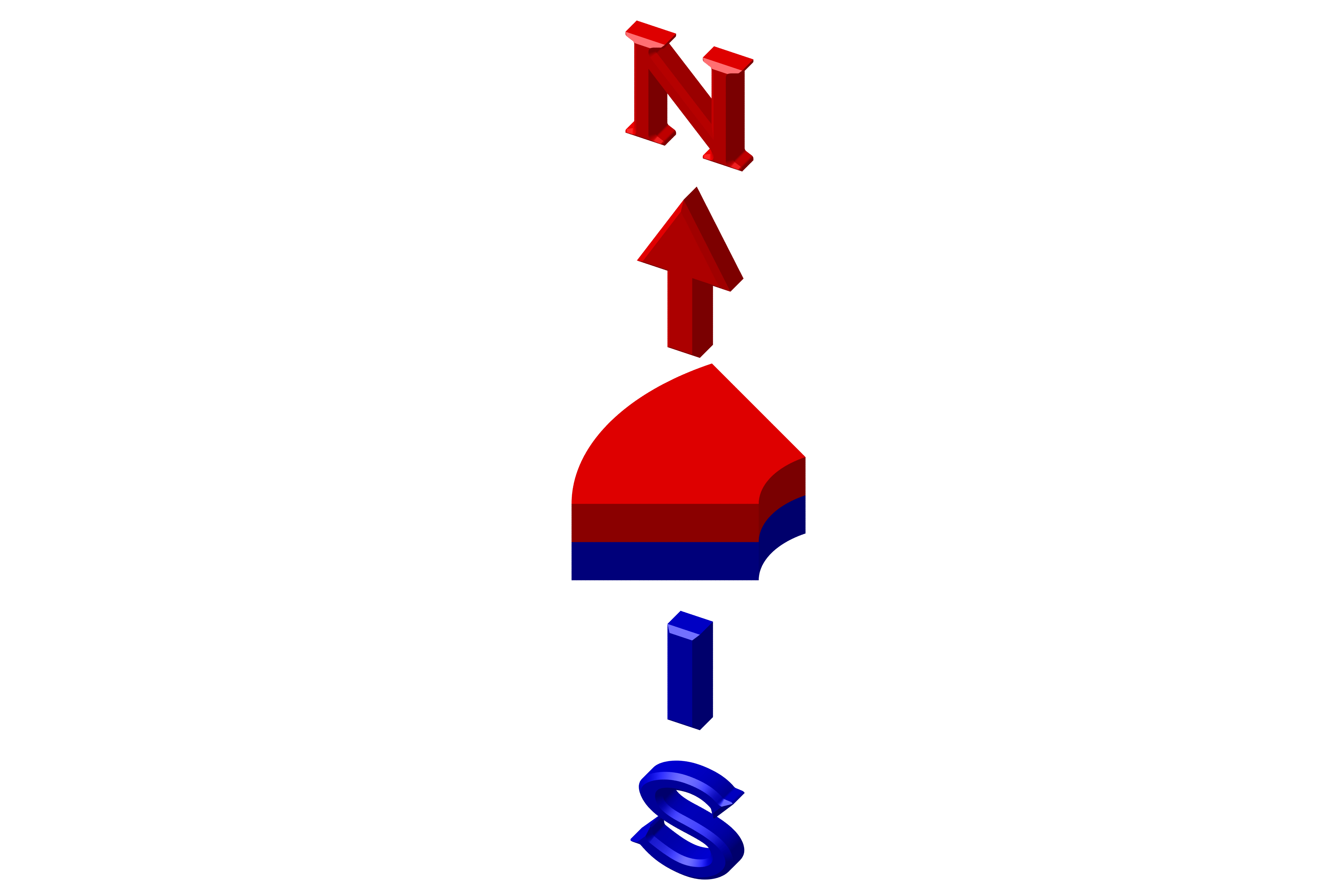

Magnetism Direction Options

We can offer several different magnetization directions, see below schematics. Their availability is limited to size. Magnetization fixture cost may apply for large and custom magnets with magnetization other than what is shown below

See the table below for cast Alnico magnet properties.

Alnico Magnet Grades & Properties

| Grade | Residual Induction Br(max) [Gs] | Max Energy Product BH (max) MGOe | Coercive Force Hcb Koe | Curie Temp. [˚C] | Temp. Coe of Br [%/˚C) | Max. Practical Operating Temp. [˚C] |

|---|---|---|---|---|---|---|

| Alnico 2 (Isotropic) |

7000 | 1.6 | 0.56 | 810 | -0.03 | 450 |

| Alnico 3 (Isotropic) |

6000 | 1.2 | 0.48 | 810 | -0.03 | 450 |

| Alnico 5 (Anisotropic) |

12500 | 5.5 | 0.64 | 860 | -0.02 | 525 |

| Alnico 6 (Anisotropic) |

10000 | 3.5 | 0.78 | 860 | -.0.02 | 525 |

| Alnico 8 (Anisotropic) |

8000 | 5.5 | 1.65 | 860 | -0.025 | 550 |

| Alnico 9 (Anisotropic) |

10500 | 9.0 | 1.50 | 860 | -0.025 | 550 |

Br: Residual Induction

Gs: Gauss

Hc: Coercive Force

Oe: Oersted

˚C: Degree Celcius

MGOe: Mega Gauss Oersted

Standard Tolerances (inches);

Rod - Diameter (±0.002), Length (±0.005)

Rectangle - Length & Width (±0.01), Thickness (±0.005)

Ring - Outside Diameter (±0.002), Inside Diameter (±0.02), Thickness (±0.005)

Sintered Alnico Magnets

They have marginally lower magnetic properties, but better mechanical properties, than cast Alnico. Their fine grain structure results in highly uniform flux distributions and mechanical strength. So they are suited for applications requiring short magnets.

See the table below for grades and properties of cast Alnico magnets.

Sintered Alnico Magnet Grades & Properties

| Grade | Residual Induction Br(max) [Gs] | Max Energy Product BH (max) MGOe | Coercive Force Hcb Koe | Curie Temp. [˚C] | Temp. Coe of Br [%/˚C) | Max. Practical Operating Temp. [˚C] |

|---|---|---|---|---|---|---|

| SAlnico 2 (Isotropic) |

7000 | 1.55 | 0.55 | 810 | 0.008 | 450 |

| SAlnico 3 (Isotropic) |

5800 | 1.20 | 0.50 | 860 | 0.011 | 550 |

| SAlnico 5 (Anisotropic) |

11000 | 4.25 | 0.62 | 890 | 0.009 | 525 |

| SAlnico 6 (Anisotropic) |

10000 | 3.50 | 0.79 | 850 | 0.011 | 525 |

| SAlnico 8 (Anisotropic) |

8800 | 5.25 | 1.50 | 850 | 0.011 | 550 |

| SAlnico 8HC (Anisotropic) |

7000 | 4.13 | 1.80 | 860 | 0.011 | 550 |

Br: Residual Induction

Gs: Gauss

Hc: Coercive Force

Oe: Oersted

˚C: Degree Celcius

MGOe: Mega Gauss Oersted

Standard Tolerances (inches);

Rod - Diameter (±0.002), Length (±0.005)

Rectangle - Length & Width (±0.01), Thickness (±0.005)

Ring - Outside Diameter (±0.002), Inside Diameter (±0.02), Thickness (±0.005)

Magnetism Direction Options

- Square and rectangular Cast or Sintered Alnico magnets can be magnetized with two poles ("N" & "S") through the length, width, thickness and multiple poles.

- Round Alnico magnet can be magnetized with two poles ("N" & "S") the thickness, diametrically and with multiple poles.

- Ring Alnico magnet can be magnetized with two poles ("N" & "S") through the thickness, diametrically and with multipoles. Contact us for the magnetism direction of irregular shapes.