Plate magnets are designed to capture unwanted ferrous metals from your product where magnetic tubes or grates might choke/bridge the product or wear out the magnetic tubes.

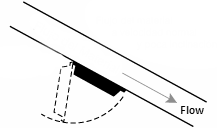

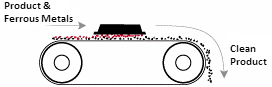

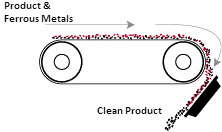

Plate magnets can be placed in chutes, over conveyor belts and below conveyor drive pulleys. Chute installation kits can include a pre-drilled piano style hinge and a handle. Plate magnets, which installed in suspended position, include four welded eyebolts.

These magnets are provided in different strength and sizes. Product depth and the distance away from the product determine the strength. Shallower product depth provides better separation of ferrous metals from product. The size is determined by chute or conveyor belt width. The most common plate magnets are listed in below tables. They are also offered with three different faces (collection area).

Smooth Face Plate Magnet

Smooth Face is recommended for conveyor installation, brittle product and for sanitary applications.

Pole Face Plate Magnet

Pole Face is recommended for the application where a stronger holding force required at the magnet face.

Tapered Face Plate Magnet

Tapered Step Face holds ferrous metals against the back of the step to prevent wash-off of captured ferrous metals in a high flow application.

Construction of Plate Magnets

Plate magnets exterior construction is from 300 series stainless steel. The pole faces and tapered step are from 400 series stainless steel. Plate magnets are offered with two magnetic loads.

- Ceramic magnetic loads are less expensive and heavier.

- Neodymium magnetic loads are more expensive, but high strength ones weigh much less than ceramic.

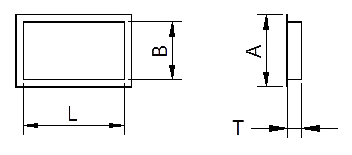

Measurements for Plate Magnets

Plate Magnets with Ceramic 5 Magnets

| Model Number | Dimension (Inches) | Magnet Reach-out* | ||

|---|---|---|---|---|

| A | B | T | ||

| PMC250 | 10 | 8 | 2 | 2.5 |

| PMC450 | 12 | 10 | 3 | 4.5 |

| PMC600 | 18 | 16 | 4.5 | 6 |

Plate Magnets with Neodymium Magnets

| Model Number | Dimension (Inches) | Magnet Reach-out* | ||

|---|---|---|---|---|

| A | B | T | ||

| PMN250 | 7.5 | 5.5 | 1.5 | 2.5 |

| PMN450 | 10 | 8 | 1.75 | 4.5 |

| PMN600 | 13 | 11 | 2.25 | 6 |

Notes:

Dimension "L" is determined by conveyor belt or chute width

*Product depth and the magnet distance from product determine magnet reach-out